ESR meter do it yourself. There is a wide range of equipment breakdowns, the cause of which is the electrolytic. The main factor of malfunction of electrolytic capacitors, this is familiar with all radio amateurs "drying", which occurs due to poor sealing of the case. In this case, its capacitive or, in other words, reactive resistance is due to the decrease in its nominal container.

In addition, in the course of work there are electrochemical reactions that enter the connection points of the conclusions with the plates. Contact deteriorates, as a result, "contact resistance" is formed, reaching sometimes up to several dozen ohm. This is also the same if the resistor is consistently connected to a serviceable condenser, and, moreover, this resistor is placed inside it. Such resistance is still referred to as "equivalent sequential resistance" or ESR.

The existence of sequential resistance adversely affects the operation of electronic devices, distorting the operation of capacitors in the scheme. Extremely strong influence has increased ESR (about 3 ... 5 Ohm) for performance, leading to the combustion of expensive chips and transistors.

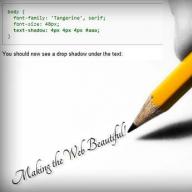

Below in the table shows the average ESR (in millime) for new capacitors of various capacitances depending on the voltage on which they are calculated.

It is no secret that reactive resistance decreases with increasing frequency. For example, at a frequency of 100 kHz and a capacity of 10μF capacitive component will be no more than 0.2 ohms. Measuring the drop in alternating voltage having a frequency of 100 kHz and above, it can be assumed that when errors in the region of 10 ... 20% of the measurement will be the active resistance of the condenser. Therefore, it is not at all difficult to collect.

Description ESR meter for capacitors

The pulse generator having a frequency of 120kHz is assembled on the logical elements of DD1.1 and DD1.2. The generator frequency is determined by the RC chain on the elements R1 and C1.

An element DD1.3 is introduced for matching. To increase the power of pulses from the generator, the elements DD1.4 ... DD1.6 are introduced into the circuit. Next, the signal passes through the voltage divider on the resistors R2 and R3 and enters the studied capacitor CX. A variable voltage measurement unit contains VD1 and VD2 diodes and a multimeter, as a voltage meter, for example, M838. The multimeter must be translated into the dial voltage measurement mode. The element ESR adjustment is carried out by changing the value of R2.

Chip DD1 - K561LN2 can be changed on K1561LN2. Diodes VD1 and VD2 Germany, it is possible to use D9, GD507, D18.

ESR meter radio components are located on which you can make with your own hands. Structurally, the device is made in one case with a nutritional element. The probe X1 is made in the form of sewed and attached to the device body, the probe x2 is no more than 10 cm long at the end of which the needle. Checking the capacitors is possible directly on the board, it is not necessary to draw them out, which greatly facilitates the search for a defective capacitor during repair.

Device setup

1, 5, 10, 15, 25, 30, 40, 60, 70 and 80 ohms.

Keeping X1 and X2 must be connected to the resistor in 1 Ohm and R2 rotation to achieve that the multimeter was 1MV. Then, instead of 1 Ω, connect the next resistor (5 Ohm) and without changing the R2 to record the point of the multimeter. The same to do with the remaining resistance. As a result, the table of values \u200b\u200bwill be obtained, which will determine the reactive resistance.

What is the main parameter to assess the health of the capacitors? Of course their container. But as the impulse high-voltage technique spread, it became obvious that it was necessary to pay attention to another parameter, on which the reliability and quality of the operation of pulsed transducers depends - this is an equivalent sequential resistance (EPS, in English. ESR - Equivalent Series Resistance). The use of capacitors with an increased value of the EPS leads to an increase in the pulsations of the output voltage compared with the calculated values, and the reversion of them is out of order due to increased heating due to the release of heat on the EPS, it is not uncommon, even cases of boiling electrolyte, deformation of the housing, as well as condensate explosions. The special severity of the negative effect of EPS is in the power pulse transducers is caused by work on large charge-discharge currents, as well as in the fact that with increasing operating frequency of EPS increases. The presence of ESR is explained by the design of the oxide capacitor and is due to the resistance of the plates, the resistance of the conclusions, the transition resistance of the contacts between the plates and leads, as well as losses in the dielectric material. Over time, the ESR condenser increases, which is not good.ESR capacitors of different types

Naturally, it is impossible to control the conclusive ohmmeter an equivalent condenser's consistent resistance - here you need a special device. On the Internet there are several simple ESR-meter constructions, but if desired, you can collect a more accurate and convenient meter on the microcontroller. For example, from Radio magazine 7-2010.

ESR condenser meter diagram

Attiny2313.

All the necessary files and firmware are in the archive. After assembling and turning on, you turn the contrast control before the inscriptions on two lines on the LCD screen appears. If there is no - check the installation and correctness of the firmware of the ATTINY2313 MK. If everything is ok - press the "Calibration" button - an amendment will be added to the firmware to the speed of the input part of the meter. Next, there will be several new electrolytic capacitors of high quality with a capacity of 220 ... 470 μF of different parties, it is best to different voltages. We connect any of them to the input slots of the device and begin to select the R2 resistor within 100 ... 470 Ohms (I got 300 ohms; you can apply a standing chain permanent + trimmed) so that the capacity of the capacity on the LCD screen has approximately similar to the condenser's nominal . To great accuracy, it is still not worth striving - will still be adjusted; then check with other condensers.

To configure the ESR meter, you need a table with the typical values \u200b\u200bof this parameter for different capacitors. This sign is recommended to be glued to the instrument housing under the display.

The following plate indicates the maximum values \u200b\u200bof the equivalent sequential resistance for electrolytic capacitors. If the measured capacitor is higher, it will not be used to work in the smoothing filter of the rectifier:

We connect a condenser 220 μF and, a minor selection of resistance resistors R6, R9, R10 (on the diagram and on my assembly drawing, designated with stars), we achieve ESR readings close to the table specified in the table. We check on all available prepared reference capacitors, incl. You can also use condensers from 1 to 100 μF.

Since to measure the capacitance capacity of 150 μF and for the ESR meter, the same section of the circuit is used, after selecting the resistance of these resistors, the accuracy of the test meter will change slightly. Now you can adjust the resistance of the resistor R2 so that these readings become more accurate. In other words, we need to select the resistance R2 - to refine the testimony of the containment of the container, adjusting the resistors in the comparator divider - to refine the ESR meter readings. Moreover, priority should be given to the internal resistance meter.

Now you need to configure the temperature of the capacitor capacitor of 0.1 ... 150 μF. Since there is a separate source of current in the diagram, the measurement of the capacitance of such capacitors can be made very accurate. We connect the capacitors of small capacity to the input slots of the device and, the selection of resistance R1 within 3.3 ... 6.8 com, we achieve the most accurate readings. This can be achieved if it is not electrolytic, and high-precision capacitors K71-1 with a guaranteed deviation of 0.15 or 1%, can be applied as reference.

When I collected this meter ESR - the scheme started immediately, only calibration was needed. This meter helped a lot when repairing BP, so the device is recommended for the assembly. The scheme developed - Desalex. , collected and experienced: sterc. .

Discuss an ESR meter article on a microcontroller

Low ESR condenser meter

The device described here allows you to measure ultra-low resistance. Initially, it was designed to verify LOW ESR capacitors - with motherboards of computers, pulse power supplies, etc. However, its application is not limited to this. The probe perfectly measures the resistance of shunts, contacts, SMD jumpers, etc. With it, you can even learn the resistance of the short segment of the wire.

The instrument description page:

On the forum in the process of discussion of the article, the RL55 participant proposed a simpler and economic generator for this meter. This modification is used in this scheme. The device is fully universal: it can be easily converted to any measurement range, which is achieved by replacing the measuring bridge resistors.

Package: Esr.lay

Briefly about work: The generator on one transistor produces a sinusoidal signal with a frequency of about 100 kHz, which is supplied to the measuring bridge. In parallel, a test capacitor is connected to one of the bridge resistors. The measurement occurs at a high frequency, since the ESR capacitor itself is highly frequency. To measure simply ultra-low resistances, the high frequency would not be needed. The transistor can be used almost any, for example - KT315, CT3102 or their analogues in SMD execution.

Voltage on the contacts of the meter is less than the voltage opening any semiconductor, so you can check the capacitors without paying from the printed circuit board.

The voltage from the measuring bridge through the boost transformer enters the direction of the arrow, where the measured resistance can be determined by deflection of the arrow. A variable resistor 4.7k is needed to install "zero" with closed senses.

The first transformer is wound on a ferrite ring with a single-core wire in isolation. The primary winding of the second transformer can also be mounted by mounting wire, and the secondary - enameled, with a diameter of 0.2mm. Rings need to pick up magnetic permeability, here you need to experiment.

Note: The printed circuit board is calculated on the use of TMS transformers from CRT monitors and the first, author, the variant of the frequency generator. Without any alteration, it is suitable for an option with transformers on ferrite rings with a generator variant from RL55, while simply another location of parts on the same contact sites and tracks is used.

When assembling the meter must be configured. A resistor in the transistor base must be achieved by the maximum amplitude of pulses on the collector when shortened applications. In this case, the signal form must be as close as possible to the sinusoidal, and the frequency is close to 100kHz. This is necessary to preserve the voltage of the contour with the condenser 22NF. Therefore, as already mentioned, you need to experiment with various rings.

When using bridge resistors with 1 ohm resistance, the device "fits" about 0.1. With a decrease in the resistance of the bridge resistors, the device can be made even more sensitive. The scale of the indicator is non-linear and it must be placed on reference SMD resistances or SMD jumpers. In the output parts, even the length of the conductors can affect resistance.

Pinzeta contacts must be performed whether better, preferably from copper. When checking parts, the contacts of the tweezers are tightly compressed, the instrument arrow variace is set to zero. Then the contacts are also tightly applied to the measured part. To check the SMD components, a platform on one of the sides of the tweezers is also made.

PR302 diodes protect the ESR meter from damage if the measured capacitor is randomly charged. Diodes in the rectifier after an increase in transformer - Germany, for smaller voltage drop. All foil polygons, in addition to the meadow, the SMD components, are covered with a colorless rebar to protect copper from atmospheric corrosion.

There is more functional

Most often, if modern radio-electronic equipment fails, electrolytic capacitors are to blame. Additional difficulties in the search for broken capacitors arise due to the fact that it is difficult to measure their container, since the capacity in the defective capacitor can be almost the same as the nominal, but the ESR will be high. Therefore, in this material and will be discussed, how to make an ESR meter with your own hands.

Most often, precisely because of the high ESR value, the correct operation of radio equipment cannot be fully implemented.

To facilitate the search for a faulty detail - we will make the manufacture of a simple analog ESR meter. The device works on the following principle: the resistance value in the condenser is checked when the frequency value \u003d 100 kHz. Capacitors whose capacity exceeds several microfrades, will have a value of approximately equal to EPS.

It is believed that the ESR meter does not need very high accuracy, in practice it is verified that the EPS in a faulty condenser is many times more than in the working element.

The process of manufacturing the device begins with the fact that the scheme is modeled in LTSpice. The names of the main functional nodes, you can observe in the diagram.

The result of modeling is this diagram on which it can be seen, for what distance the arrow in the microammeter is to donate, taking into account the ESR indicators.

Taking the results of the LTSPICE schema, you can build a circuit diagram in ORCAD. The device is powered by feeding 9 V, and to stabilize the voltage using the LM7805 microcircuit. In addition, in order to make the ESR meter with your own hands, you will have to use the transistors 2N3904 (N-P-N) and 2N3906 (P-N-P), however, the normal operation of the scheme will be provided with any common transistors. In the choice of diodes, we will stop at 1N5711. The current of the measuring head is 50 μA.

The value of the maximum voltage on the contacts of the measured condenser is not more than 100 mV, which makes it possible for using the device with intrahemnal (without supplying the condenser) testing.

Here you can observe the appearance of the wiring of the board, it has one side, and there are no jumpers in it. We try to use SMD elements, though, some mounting holes will still need.

The manufacture of the printed circuit board was carried out on the CNC machine, the carpentry was carried out, however, it is quite possible to use the LUT-Ohm or photoresist.

The image shows the board for which the components are already attacked:

The measurement of values \u200b\u200bon the scale is performed by practical use using the connection of precision resistors having different resistance in the range of 0.1 - 10 ohms. Ricoving the scale is made using CorelDRAW, after which the scale is printed using photographic paper.

The assembly process at the completion stage. The image shows the inner side of the ESR meter.

And here is the finished device:

Before proceeding to measurements, the condensers should be discharged. With a flow current of 26 mA, if you eat from the "Crown" battery, then the continuous operation of the device can be carried out during the day.

That's it! Now you can make an ESR meter with your own hands. It is only a little patience and a minimum of tools.

Many thanks for the work done. Another conclusions on the basis of the read: The head in 1 ma turned out to be a tup for such a detector. After all, it is the inclusion consistently with a resistor head stretches the scale. Since great accuracy you do not need to try the head from the tape recorder. (one trouble she is pretty electrically electrified, a slightly sleeve sweaters and the arrow itself on the floor scale jumps) and the current of full deviation is about 240 μA (accurate name M68501)

But in general, so that the capacitor should be seed not enough by the scale of OM to 10-12?

Multimeter Prefix - MeterESR.

The ideal condenser, working on alternating current, should have only reactive (capacitive) resistance. The active component must be close to zero. Really, a good oxide (electrolytic) capacitor must have an active resistance (ESR) not more than 0.5-5 ohms (depends on the tank, rated voltage). Practically, in the equipment that has worked for several years, you can meet, it would seem a good capacitor with a capacity of 10 μF with ESR to 100 ohms and more. Such a capacitor, despite the presence of a container, is indignantly, and most likely causes the malfunction or poor-quality work of the device in which it works.

Figure 1 shows the sequence scheme to the multimeter to measure ESR oxide capacitors. To measure the active component of the resistance of the capacitor, it is necessary to select this measurement mode, in which the reactive component will be very small. As is known, the reactive resistance of the container decreases with increasing frequency. For example, at a frequency of 100 kHz with a capacity of 10 μF, the reactive component will be less than 0.2 ohms. That is, measuring the resistance of an oxide capacitor with a capacity of more than 10 μF to fall on it alternating voltage with a frequency of 100 kHz and more, it can be argued that. With a given error of 10-20%, the measurement result can be taken almost only as the value of active resistance.

Also, the scheme shown in Figure 1 is a 120 kHz frequency pulse generator, made on the logical inverters of the chip D1, a voltage divider consisting of resistances R2, R3 and a tested capacitor of CX, and a variable voltage meter on CX consisting of a VD1 detector -VD2 and multimeter included on the measurement of small constant stresses.

The frequency is set by the R1-C1 chain. The element D1.3 is matching, and the output cascade is made on the elements D1.4-D1.6.

The resistance adjustment R2 perform the adjustment of the device. Since in the popular multimeter M838 there is no mode of measurement of small variables of stresses (namely, the author has a prefix with this device), in the probe scheme there is a detector on the VD1-VD2 germanium diodes. The multimeter measures the constant voltage on C4.

The power source serves "Crohn". This is the same battery as the one that feeds the multimeter, but the prefix must be powered by a separate battery.

Installation of parts of the console is made on the printed circuit board, the layout and location of the parts of which are shown in Figure 2.

Structurally, the prefix is \u200b\u200bmade in one case with a power source. To connect to the multimeter, their own multimeter probes are used. The case is the usual soapbox.

From points X1 and X2 are made short probe. One of them is hard, in the form of sewing, and the second flexible length is no more than 10 cm, the eye-delicate is the same pointed dipstick. These probes can be connected to condensers, as unconfied, so to the board located on the board (it is not required to fall out), which greatly simplifies the search for a defective capacitor during repair. It is advisable to choose to these crocodile tails for the convenience of checking unconfied (or dismantled) capacitors.

The K561LN2 chip can be replaced with a similar K1561LN2, ECR561LN2, and with changes in the board - K564LN2, CD4049.

D9b diodes are any accordion, for example, any D9, D18, GD507. You can try to apply and silicon.

Switch S1 - microtumbler presumably Chinese production. He has flat conclusions for printed installation.

Establishing the console. After checking the installation and efficiency, connect the multimeter. It is desirable to check the frequency or oscilloscope to check the frequency on x1-x2. If it lies within 120-180 kHz, normal. If not, - pick up the resistance R1.

Prepare a set of permanent resistors with resistance of 1 Ohm, 5 Ohm, 10 ohms, 15 ohms, 25 ohms, 30 ohms, 40 ohms, 60 ohms, 70 ohms and 80 ohms (or so). Prepare a sheet of paper. Connect the resistor resistor 1 ohm instead of the test condenser. Rotate the R2 slider so that the multimeter show the voltage of 1 mV. On paper, write "1 Ohm \u003d 1mV". Next, connect other resistors, and without changing the position R2, make similar records (for example. "60Ω \u003d 17mv").

It turns out a multimeter reading table. This table must be accurately arranged (manually or on the computer) and paste the console on the body, so that the table is convenient to use. If the table is paper, - cover your tape tape on its surface to protect paper from abrasion.

Now, checking the capacitors, you read the multimeter readings in millivatts, then on the table approximately define the ESR condenser and decide on its suitability.

I want to note that this prefix can be accommodated for measuring the capacity of oxide capacitors. To do this, it is necessary to significantly lower the frequency of the multibulator, connecting the C 1 capacitor parallel with a capacity of 0.01 μF. For convenience, you can make the "C / ESR" switch. It will also be necessary to make another table - with the values \u200b\u200bof tanks.

It is desirable, to connect to a multimeter to use the shielded cable to eliminate the influence of the press on the multimeter reading.

The device, on the board of which you are looking for a faulty capacitor, must be turned off at least half an hour before the search for searching (so that the capacitors existing in its scheme are discharged).

The console can be used not only with a multimeter, but also with any device capable of measuring the malels of direct or alternating voltage. If your device is able to measure a small variable voltage (Millivoltmeter of AC or Dear Multimeter), you can detector on VD1 and VD2 diodes not to do, and measure the variable voltage directly on the test condenser. Naturally, a sign should be done under a specific device with which you plan to work in the future. And in the case of using an instrument with an arrow indicator, you can apply an additional scale to the ESR measurement scale.

Radio constructor, 2009, №01 p. 11-12

Literature:

1 with Roechin. Prober of oxide capacitors Radio, No. 10, 2008, p.14-15.

For more than a year, I use the device according to the scheme of D. Telesh from the magazine "Schedule" No. 8, 2007, p. 44-45.

On the Millivoltmeter M-830B in the 200 mV range of the testimony, without a prescribed capacitor, is 165 ... 175 mV.

Power supply 3 V (2 AA batteries worked more than a year), measurement frequency from 50 to 100 kHz (installed 80 kHz selection of capacitor C1). Practically measured the containers from 0.5 to 10,000 μF and ESR from 0.2 to 30 (when the testimony of the instrument's readings in MV complies with the resistors of the same nominal in OM). Used to repair pulsed power supplies PC and BREA.

Virtually ready-made scheme for verification of EPS, if you gather on CMOS, it will work from 3 volts ....

ESR-meter

That is, the device for measuring EPS is an equivalent sequential resistance.

As it turned out, the performance of (electrolytic - particular) capacitors, especially those that work in power pulse devices, affects a large extent an internal equivalent sequential resistance to variable current. Various capacitor manufacturers are different to the frequency values \u200b\u200bon which the EPS value should be determined, but this frequency should not be below 30 kHz.

The amount of EPS to some extent is associated with the main parameter of the condenser - capacity, but it has been proven that the capacitor can be faulty due to the large eigenvalue value of the EPS, even with the presence of the claimed capacity.

view from the outside

As a generator, the CR1211EU1 microcircuit is used (the frequency at a diagram in about 70 kHz), transformers can be applied phase inverter from BP AT / ATH - the same parameters (transformation coefficients in particular) from almost all manufacturers. Attention!!! In the T1 transformer, only half the winding is used.

The head of the device has a 300mk sensitivity, but it is possible to use other heads. Preferably, the use of more sensitive heads.

The scale of this device is stretched by one third when measuring until the 1st Ohm. The tenth Ohm is easily distinguishable from 0.5 Ohm. 22 ohms are stacked in the scale.

Stretching and range can be varied by adding turns to the measuring winding (with suctions) and / or to the windings of the III of a transformer.

http: // www. Matei. RO / Emil / Links2.php

http: // www. . AU / CMS / Gallery / Article. HTML? Slideshow \u003d 0 & a \u003d 103805 & i \u003d 2

Div_adblock308 "\u003e

http: // forum. / index. php? Showtopic \u003d 42955 & ST \u003d 40

Capacity meter from 0.5 to 30,000 μF. If you increase the frequency of the generator to 100 kHz, then it can be measured and EPS.

Limits: 0-50, 0-500, ICF

http: // ***** / index. php? Act \u003d Categories & Code \u003d Article & Article \u003d 2386

As the basis of all the meters, the generator was taken with an output frequency of 50-100 kHz and the voltage or current meter, the test capacitor was included between them and its internal resistance was determined by the indications of the arrow or LED indicator. Some meters have sufficiently high indicators and rather reliable ways to protect against voltage from the charged condenser checked, on the input of the instrument.

When connecting a good capacitor, the LED should go out completely, since the short-circuited turns completely disappear generation. With defective capacitors, the LED continues to burn or slightly presses, depending on the ESR value.

Simplicity of this probe, allows you to assemble it in the case from a conventional marker, the main place in it is paid to the battery, the switch button and the LED protruding over the case. The miniature of the probion allows you to place one of the probe, in the same place, and the second to be made as short as possible, which will reduce the effect of inductance of the probe, on the testimony. In addition, it is not necessary to turn your head, for visual control of the indicator and the installation of probe, which is often inconvenient during the work.

Construction and details.

The transformer coils are wound on one ring, preferably the smallest size, its magnetic permeability is not very important, the generator has the number of turns of 30 waters. Each indicator - 6 waters. and measuring 4 waters. or 3 waters. (selected when setting up), the thickness of all wires is 0.2-0.3 mm. The measuring winding should be mounted with a wire of at least 1.0 mm. (The mounting wire is quite suitable - only the winding fit on the ring.) R1 adjusts the frequency and consumed current in small limits. The R2 resistor limits the short circuit current created by the test capacitor, it, for considerations of protection against a charged condenser, which is discharged through it and the winding must be 2-watt. Variating it with resistance, you can easily distinguish the resistance from 0.5 ohms and above, on the luminescence of the LED. The transistor will suit any low-power. Power is carried out from one 1.5 volt battery. During the test of the device, it was even possible to power from two probes of the arrow ohmmeter included on the unit.

Nominal details:

ROM.

R2 * - 1OM

C1-1 1 μF

C2-390pf

Setting.

No difficulties. The correctly assembled generator begins to work immediately at a frequency of 50-60 kHz, if the LED does not light up, you need to change the polarity of inclusion. Then connecting to the measuring winding instead of the condenser a resistor 0.5-0.3 Oma seek barely noticeable luminescence, picking up the turns and resistor R2, but usually their number ranges from 3 to 4. At the end, check on a deliberately good and defective condenser. If there are small skills, the ESR condenser is easily recognized to 0.3-0.2 Ohm, which is enough to find a faulty capacitor, from the capacity of 0.47 and to 1000 mg. Instead of one LED, you can put two and in the chain of one of them to turn on the stabilion by 2-3 volts, but you will need to increase the winding, and the device is constructively complicated. You can immediately make two probe coming from the housing, but the distance between them should be provided, so that it is convenient to measure various in terms of magnitude, condensers. (for example - for SMD capacitors, you can use the idea of \u200b\u200bBarbos "A - and constructively perform a plot in the form of a tweezers)

Another application of this instrument: it is convenient to check the control buttons in audio and video equipment, since, over time, some buttons give false commands due to increased internal resistance. Also concerns and checking printed conductors to break or check the transitional contact resistance.

I hope the probe will take a worthy place in the ranks of the instrument-assistants of the Zusostroyer.

The impression of using this probe:

- I forgot what a faulty condenser is;

- 2/3 of old capacitors had to throw out.

Well, the most pleasant thing is to the store and I do not go to the market without a probe.

Condenser sellers are very unhappy.

Capacity and inductance meter

E. Terentyev

Radio, 4, 1995

http: // www. ***** / SHEM / SCHEMATICS. HTML? di \u003d 54655.

The proposed arrow gauge allows you to determine the parameters of the majority in the practice of the radio amateur of inductors and capacitors. In addition to measuring element parameters, the device can be used as a fixed frequency generator with a decade division, as well as a label generator for radiotechnical measuring instruments.

The proposed tank meter and inductance differs from the same ("Radio", 1982, 3, p.47) simplicity and low labor-intensity of manufacture. The measurement range is divided into six subbands with limit values \u200b\u200bof the capacity of 100 PF - 10 μF for capacitors and inductance 10 μH - 1 GN for inductance coils. The minimum values \u200b\u200bof the measured containers, the inductance and the accuracy of measurement of parameters at the limit 100 of the PF and 10 μH determines the structural container of the terminals or jacks to connect the terminals of the elements. On the rest of the subbands, the measurement error is mainly determined by the class of accuracy of the gear measuring head. The current consumed current does not exceed 25 mA.

The principle of operation of the device is based on measuring the average value of the discharge current of the capacitor capacity and the self-induction of inductance. The meter, the schematic diagram of which is shown in Fig. 1, consists of a specifying generator on elements DD1.5, DD1.6 with a quartz frequency stabilization, frequency divider line on DD2 chips - DD6 and buffer inverters DD1.1 - DD1.4. The R4 resistor limits the output current of the inverters. The chain of elements VD7, VD8, R6, C4 is used when measuring the container, and the chain VD6, R5, R6, C4 - when measuring inductance. The VD9 diode protects the micronmmeter PA1 from overload. C4 capacitor C4 is selected relatively large to reduce the jitter of the arrow at the maximum measurement limit, where the clock frequency is minimal - 10 Hz.

The instrument uses a measuring head with a total deviation current of 100 μA. If you apply more sensitive - by 50 μA, then in this case you can reduce the measurement limit by 2 times. The ALS339A seven LED indicator is used as an indicator of the parameter measured, it can be replaced by the ALS314A indicator. Instead of a quartz resonator at a frequency of 1 MHz, a mica or ceramic capacitor can with a capacity of 24 PF, however, the measurement error will increase by 3-4%.

Replacements of diode D20 diodes D18 or GD507, Stabitron KS156A - X147A stabitron, KS168A. Silicon diodes VD1-VD4, VD9 can be any maximum current of at least 50 mA, and the VT1 transistor is any of the types of CT315, KT815. Condenser CZ - Ceramic K10-17A or KM-5. All nominal elements and quartz frequency may differ by 20%.

The instrument setting starts in the measurement mode of the container. The SB1 switch to the upper position is translated and installed the SA1 range switch to the position corresponding to the measurement limit of 1000 PF. By connecting an exemplary capacitor with a capacity of 1000 PF to terminals XS1, XS2, the R6 trimmer engine is displayed in which the PA1 micronomer arrow will be installed to the final division of the scale. Then translate the SB1 switch to the inductance measurement mode and, by connecting the inductor of the inductor of 100 μg to the terminals, in the same position of the SA1 switch, it produces a similar calibration with a R5 trimming resistor. Naturally, the accuracy of the calibration of the device is determined by the accuracy of the exemplary elements used.

Measuring the measurements of the parameters of the elements is desirable to start with a larger measurement limit to avoid sharp setting the arrow of the instrument head. To ensure power supply, you can use a constant voltage of 10 ... 15 V or alternating voltage from the appropriate winding of the transformer of another device with a load current of at least 40 ... 50 mA. The power of a separate transformer must be at least 1 W.

In the case of powering the device from battery batteries or electroplating elements 9 in it, it can be simplified and improving the cost-effectiveness of the diodes of the power supply rectifier, the HG1 indicator and the SB1 switch, bringing three terminals to the front panel of the instrument 1, 2, 3, specified On the concept. When measuring the capacitance, the capacitor is connected to terminals 1 and 2, when measuring inductance, the coil is connected to terminals 1 and 3.

Editorial note. The accuracy of the LC meter with an arrow indicator to a certain extent depends on the scale of the scale, so the introduction into the circuit of the switched frequency divider to 2, 4 or a similar change in the frequency of the specifying generator (for an option without a quartz resonator) reduces the requirements for dimensions and the accuracy class of the showing device.

LC Pierce Meter to Digital Voltmeter

http: ///izmer/izmer4.php.

The digital measuring device in the radio amateur laboratory is now not uncommon. However, it is not often possible to measure the parameters of the capacitors and inductor coils, even if it is a multimeter. The simple prefix described here is designed for use in conjunction with multimeters or digital voltmeters (for example, M-830B, M-832 and them like) that do not have the measurement mode of the parameters of the jet elements.

To measure capacity and inductance using an easy console, a principle was used in detail in Article A. Stepanov "Simple LC-meter" in Radio No. 3 for 1982. The proposed meter is somewhat simplified (instead of the generator with a quartz resonator and a decade frequency divider applied Multivibrator with a switching frequency of generation), but it allows with sufficient to practice accuracy to measure the container in the range of 2 PF ... 1 μF and the inductance of 2 μH ... 1 GG. In addition, it produces a rectangular voltage with fixed frequencies of 1 MHz, 100 kHz, 10 kHz, 1 kHz, 100 Hz and an adjustable amplitude from 0 to 5 V, which expands the device.

The specifying meter generator (Fig. 1) is made on the elements of the chip DD1 (CMOS), the frequency at its output is changed using the SA1 switch in the range of 1 MHz - 100 Hz, connecting C1-C5 capacitors. From the generator, the signal enters the electronic key collected on the VT1 transistor. SA2 switch select the measurement mode "L" or "C". In the switch shown on the circuit, the prefix measures the inductance. The measured inductance coil is connected to the jacks x4, x5, the capacitor to xs, x4, and the voltmeter to the jacks x6, x7.

When operating a voltmeter, it is set to the measurement mode of the constant voltage with the upper limit of 1 - 2V. It should be noted that at the output of the console, the voltage varies in the range of 0 ... 1 V. on the jacks x1, x2 in the measurement mode of the tank (the SA2 switch - in the "C" switch) is there a adjustable rectangular voltage. Its amplitude can be smoothly changed by a variable R4 resistor.

The prefix from the GB1 battery with a voltage is 9 V ("Corundum" or similar to it) through the stabilizer on the VT2 transistor and VD3 stabilion.

Chip K561L7 can be replaced by K561L5 or K561L9 (excluding DD1.4), transistors VT1 and VT2-on any low-power silicon relevant structure, VD3 stabilitron will be replaced by KS156A, X168A. Diodes VD1, VD2 are any point Germany, for example, D2, D9, D18. Switches are desirable to use miniature.

The body of the device is homemade or ready-made suitable sizes. Installation of parts (Fig. 2) in the housing - mounted on switches, R4 resistor and nests. The appearance variant is shown in the figure. HZ-X5 connectors are homemade, made of leaf brass or copper with a thickness of 0.1 ... 0.2 mm, the design of them is understandable from fig. 3. To connect the capacitor or coil, it is necessary to introduce the findings of the part until it stops into the wedge-shaped clearance of the plates; This achieves fast and reliable fixation of the conclusions.

Establishment of the device is made using a frequency meter and an oscilloscope. The SA1 switch is transferred to the upper position and selection of the C1 condenser and the resistor R1 achieve frequencies of 1 MHz at the generator output. The switch is then sequentially translated into subsequent positions and the selection of C2 - C5 capacitors set the generation frequencies of 100 kHz, 10 kHz, 1 kHz and 100 Hz. Next, the oscilloscope is connected to the VT1 transistor collector, the SA2 switch - in the measurement position of the container. The selection of the resistor R3 achieve the shape of oscillations close to Meandra on all bands. Then, the SA1 switch is again installed in the upper position according to the scheme, to the nates x6, x7 are connected to a digital or analog voltmeter, and to the slots xs, x4 - an exemplary capacitor with a capacity of 100 PF. The adjustment of the resistor R7 is achieved by the testimony of the voltmeter 1 V. Then translate the SA2 switch to the inductance measurement mode and to the jacks x4, x5 connect the exemplary coil with an inductance 100 μH, the R6 resistor set the voltmeter readings, also equal to 1 V.

On this instrument setting ends. On the remaining ranges, the accuracy of the testimony depends only on the accuracy of the selection of capacitors C2 - C5. From the editorial The generator setting is better to start from the frequency of 100 Hz, which is set by the selection of the resistor R1, the C5 capacitor is not selected. It should be remembered that Capacitors SZ - C5 must be paper or, better, metapilene (K71, K73, K77, K78). With limited capabilities in the selection of capacitors, you can also use the switching section SA1.2 resistors R1 and their selection, and the number of condensers must be reduced to two (C1, SZ). Ratings of resistance of resistors will be in this: the case of 4.7: 47; 470 k0m.

(Radio 12-98.

List of sources on the subject of capacitor EPS in the Radio magazine

Prober of oxide capacitors. - Radio, 2003, №10, p.21-22. EPS and not only ... - Radio, 2005, №8, p.39.42. Device for testing oxide capacitors. - Radio, 2005, №10, p.24-25. Evaluation of equivalent condenser consistent resistance. - Radio, 2005, №12, p.25-26. EPS meter of oxide capacitors. - Radio, 2006, №10, p. 30-31. EPS indicator of oxide capacitors. - Radio, 2008, №7, p.26-27. EPS meter of oxide capacitors. - Radio, 2008, №8, p. 18-19. Prober of oxide capacitors. - Radio, 2008, №10, p.14-15. EPS meters of oxide capacitors. - Radio, 2009, №8, from 49-52.

Capacitator tank meter

V. Vasilyev, Naberezhnye ChelnyThis device is built on the basis of the device previously described in our journal. Unlike most such devices, it is interesting to the fact that the control of the health and capacity of the capacitors is possible and without dismantling it from the board. In operation, the proposed meter is very convenient and has sufficient accuracy.

The one who is engaged in the repair of household or industrial radio equipment knows that the serviceability of the capacitors is conveniently checked without dismantling them. However, many condenser tank meters are not provided. True, one similar structure was described in. It has a small measurement range, a non-linear countdown scale, which reduces accuracy. When designing a new meter, the task of creating a device with a wide range, a linear scale and direct sample, so that it can be used as laboratory. In addition, the device must be diagnostic, i.e., capable of checking and capacitors, drawn P-N transitions of semiconductor devices and resistance of resistors.

The principle of operation of the device is such. A trianal shape voltage is supplied to the input of the differentiation of the differentiation of the capacitor as a differentiator. At the same time, on its outlet, a meander with an amplitude proportional to this capacitor is obtained. Next, the detector allocates the amplitude value of the meander and gives constant voltage to the measuring head.

The amplitude of the measuring voltage on the appliance applications is about 50 mV, which is not enough to open the R-N transitions of semiconductor devices, so they do not have their own shunt action.

The device has two switches. Switch limits "Scale" with five positions: 10 μF, 1 μF, 0.1 μF, 0.01 μF, 1000 PF. The "multiplier" switch (x1000, x100, x10, x1) changes the frequency of measurement. Thus, the device has eight subbands of measuring tank from 10,000 μF to 1000 PF, which is almost sufficient in most cases.

The generator of triangular oscillations is assembled on the DA1.1, DA1.2, DA1.1 chip (Fig. 1). One of them, DA1.1, works in a comparator mode and generates a rectangular signal that enters the input of the integrator DA1.2. The integrator converts rectangular oscillations into triangular. The generator frequency is determined by the elements R4, C1-C4. In the feedback circuit of the generator, there is an inverter on the DA1.4 OU, which provides an auto-oscillating mode. SA1 switch can be installed one of the measurement frequencies (multiplier): 1 Hz (x1000), 10 Hz (x100), 100 Hz (x10), 1 kHz (x1).

Fig. one

OU DA2.1 - voltage repeater, at its output signal triangular amplitude amplitude of about 50 mV, which is used to create a measuring current through a valid capacitor CX.

Since the capacitance of the capacitor is measured in the board, there may be a residual voltage on it, therefore, two counter-parallel VD1 bridge diodes are connected to exclude it with its damage to the meter.

OU DA2.2 works as a differential and actuates the role of a current converter - voltage. Its output voltage: Up \u003d (R12 ... R16) IVH \u003d (R12 ... R16) CX DU / DT. For example, when measuring the capacity of 100 μF at a frequency of 100 Hz, it turns out: II \u003d CX DU / DT \u003d 100 100 MV / 5 MS \u003d 2MA, UIV \u003d R16 IVH \u003d 1 coma \u003d 2 V.

Elements R11, C5-C9 are necessary for the sustainable operation of the differential. Capacitors eliminate oscillatory processes on the fronts of the meander, which make it impossible to accurately measure its amplitude. As a result, at the output of DA2.2, a meander is obtained with smooth fronts and an amplitude proportional to the measured tank. The R11 resistor also limits the input current at closed probe or when the capacitor is pierced. For the input chain of the meter, inequality should be performed: (3 ... 5) SCR11<1/(2f).

If this inequality is not fulfilled, then in half the current of the current IVH does not reach the steady value, and the meander is the corresponding amplitude, and the error occurs in the measurement. For example, in the measuring device described in, when measuring the capacity of 1000 μF at a frequency of 1 Hz, a time constant is defined as CX R25 \u003d 1000 ICF 910 Ohm \u003d 0.91 s. Half of the period of oscillations of T / 2 is only 0.5 s, therefore, on this scale, the measurements will be noticeably nonlinear.

The synchronous detector consists of a key on the VT1 field transistor, the key control node on the DA1.3 and the cumulator C10. The DA1.2 OU gives the control signal to the VT1 key during the positive Malendra half-wave when its amplitude is installed. Condenser C10 remembers a constant voltage isolated by the detector.

From the C10 condenser, the voltage carrying information on the value of the CX capacitance, through the repeater Da2.3 is supplied to the micronmmeter of the RA1. Capacitors C11, C12 - smoothing. From the Machine of the Variable Calibration Resistor R22, a voltage is removed on a digital voltmeter with a measurement limit of 2 V.

Power source (Fig. 2) issues two-polar stresses ± 9 B. Support voltages form thermostable stabilids VD5, VD6. Resistors R25, R26 set the required output voltage value. Structurally, the power source is combined with a measuring part of the device on a common circuit board.

Fig. 2.

The device uses variable resistors of the SPZ-22 type (R21, R22, R25, R26). Permanent resistors R12-R16 - type C2-36 or C2-14 with a permissible deviation ± 1%. Resistance R16 is obtained by a connection of sequentially selected resistors. Resistance resistors R12-R16 can also be used by other types, but they must be chosen using a digital ohmmeter (multimeter). The remaining permanent resistors are any scattering capacity of 0.125 W. Condenser C10 - K53-1 A, CONDENSERS C11-C16 - K50-16. CONDENSERS C1, C2 - K73-17 or other metal floss, SZ, C4 - km-5, km-6 or other ceramic with TKA are not worse than the M750, they must also be chosen with an error of no more than 1%. The remaining condensers are any.

Switches SA1, SA2 - P2G-3 5P2N. In the design, it is permissible to apply the KP303 (VT1) transistor with the iconic indices A, B, B, F, I. Transistors VT2, VT3 voltage stabilizers can be replaced by other low-power silicon transistors of the appropriate structure. Instead of the OU K1401UC4, it is possible to use K1401UD2A, but then an error is possible at the limit "1000 PF" due to the displacement of the differentiator input created by the input current DA2.2 on R16.

The T1 power transformer has an overall power of 1 W. It is permissible to use a transformer with two secondary windings of 12 V, but then two rectifier bridges are necessary.

A oscilloscope will be required to configure and debug instrument. It is not bad to have a frequency meter to check the frequencies of the generator of triangular oscillations. We also need exemplary capacitors.

The device is starting to customize the voltage settings +9 B and -9 in using resistors R25, R26. After that, they check the operation of the triangular oscillation generator (oscillograms 1, 2, 3, 4 in Fig. 3). If there is a frequency meter, the generator frequency is measured at different positions of the SA1 switch. It is permissible if frequencies differ from the values \u200b\u200bof 1 Hz, 10 Hz, 100 Hz, 1 kHz, but among themselves they should differ exactly 10 times, since the correctness of the instrument readings on different scales depends on this. If the generator frequencies are not painted ten, then the necessary accuracy (with an error of 1%) is achieved by the selection of capacitors connected parallel to C1-C4 capacitors. If the capacitances of C1-C4 capacitors are selected with the necessary accuracy, you can do without measuring frequencies.