Multi-turn actuators SA 07.1 - SA 48.1 for shut-off operation are designed for short-term operation from 2 to 15 minutes. The special reduced torque version is designed for duty cycles from 2 to 30 min.

Actuators types SA 07.1 - SA 16.1 can be combined with various control systems. From a simple OPEN-CLOSE control to a micro controlled version with working data latching or a digital interface.

Design features

Multi-turn actuators are used where automation is required. It is possible to adapt their work to any requirements. This is possible thanks to:

- Wide range of torques.

- Various combinations with gearboxes. Any multi-turn actuator can be modified and turned into a lever or linear actuator.

- A wide variety of existing modifications.

AUMA multi-turn actuators are characterized by the following:

- Torque range from 10 Nm to 32,000 Nm

- Output speed 4 to 180 rpm

- Displacement and torque trip

- Output forms in accordance with the ISO standard

- Compatible with 3-phase AC, 1-phase AC and DC motors

Environmental conditions:

- High shell protection

- High degree of corrosion protection

- Wide temperature applicability range

Options:

- Intermediate position switches

- Switches in tandem version

- Remote position sensor

- Magnetic position and torque sensor

- Mechanical position indicator

Interfaces:

- AUMA electrical plug connection (terminals optional)

- Threaded cover for cable glands

- Output forms according to ISO and DIN standards.

The ESCO company provides an opportunity to purchase high-quality equipment at affordable prices. The catalog presents a variety of elements of valves, as well as important details that complement their work. This is in particular the AUMA electric drive, which is manufactured in Germany. This fact alone speaks of the reliability of the product: it meets European standards and perfectly copes with its tasks, withstanding harsh operating conditions.

AUMA actuator modifications

- AUMA actuators models SA 07.1 - SA 16.1 and SAR 07.1 - SAR 16.1, which have the following characteristics:

- torque within 10 - 1,000 Nm,

- output speed - 4 - 180 rpm. - AUMA actuators models SA 25.1 - SA 48.1 and SAR 25.1 - SAR 30.1 with the following operating parameters:

- torque varies from 630 to 32,000 Nm,

- output speed - 4-90 rpm. - Part-turn actuators from AUMA, used where automated rotation of no more than 360 degrees is required. This type of drive is most often used in the chemical, petrochemical, pharmaceutical industries, as well as in power plants, in the field of heat supply, wastewater treatment, for equipping pumping stations, water treatment plants, shipbuilding, metallurgical plants, and food industry enterprises. In turn, AUMA part-turn actuators are divided into:

- part-turn with integrated control (for example, electric actuator model AUMA MATIC),

— part-turn with MATIC control in customized design.

The listed types of AUMA electric actuators are designed for an operating time of up to 15 minutes, which meets the standard requirements for valves of this kind. For operation up to 30 minutes, drives in a special design are provided.

Customers are presented with various configurations of goods, for example, the AUMA SA07 2 electric actuator or the AUMA SA14 electric actuator, the difference between which is the torque.

One of the advantages of AUMA electric actuators is their versatility: they are perfectly combined with various valves from foreign and domestic manufacturers. These are, in particular, AVK valve, Hawle valve, cast iron valves MZV and MZVG.

The scope of AUMA actuators is very wide:

- petrochemical industry;

- pharmaceuticals;

- power plants;

- shipbuilding;

- locks, dams, wastewater treatment;

- metallurgy;

- air conditioning;

- heat supply;

- air pollution control;

- heat supply;

- pumping stations;

- cement industry;

- light industry and much more.

Multi-turn actuator AUMA SA 07.2 - SA 16.2

Type / series:SA 07.2 - SA 16.2 / NORM

Design features:

— Working mode:

short-term S 2 - 15 min.

re-short-term S 4 - 25%.

— Self-braking:

at speeds up to 90 rpm. (50 Hz)

108 rpm (60 Hz).

— Electric motor:

three-phase asynchronous, version IM B9 according to IEC 60034.

— Insulation class:

F Tropicalized - Standard

H, tropical version is an option.

— Motor protection:

thermal switches (NC) - standard

thermistors (PTC according to DIN 44082) optional.

— Degree of protection: IP 68 is standard.

— Corrosion protection:

KS - standard

KX, KX-G - option.

— Automation:

Auma MATIC, AUMATIC control units are an option.

Technical data:

Electric drive type: multiturn.

Control mode: open close.

Execution type: general industrial.

Model: NORM.

Working mode: short-term.

Temperature range (С°): -40…+80.

Torque (Nm): 10 — 1000.

Cr. adjusting torque (Nm): 30.

Rotation speed (rpm): 4 — 180*.

Electric motor: 3-phase asynchronous, version IM B9 according to IEC 60034.

Power ~ (B): 220 - 500 V, 50 - 60 Hz.

Protection class: IP68.

Automated fittings: Gate valves, Gate valves.

A large number of options are available in terms of housing options, temperature ranges, wiring diagrams, applicable types of microswitches, as well as combinations with control units and reduction gears.

Electric drives SA 07.2, SA 07.6, SA 10.2, SA 14.2, SA 14.6, SA 16.2 are second generation drives and are recommended for use instead of drives SA 07.1, SA 07.5, SA 10.1, SA 14.1, SA 14.5, SA 16.1

Product range:

|

Torque |

Frequency |

Manual |

Weight, kg) |

|

|

SA07.2/F07 |

||||

|

SA07.2/F10 |

||||

|

SA07.6/F07 |

||||

|

SA07.6/F10 |

||||

|

SA10.2/F10 |

||||

|

SA14.2/F14 |

||||

|

SA14.6/F14 |

||||

|

SA16.2/F16 |

Electric actuators for automation of industrial valves AUMA S.A. Degree of protection IP 68.Corrosion protection up to C5 in accordance with EN ISO 12944-2.

AUMA actuators can be integrated into any conventional DCS. They are available in configuration with control unitsAMExC or ACExC.

Drives with built-in controls ready for operation immediately after connection to the power supply and can be controlled using local control.

Depending on the version, commissioning can be carried out without tools and without opening the device housing.

The range includes electric drives:

- AUMA SA 07.2

- AUMA SA 07.6

- AUMA SA 10.2

- AUMA SA 14.2

- AUMA SA 14.6

- AUMA SA 16.2

- AUMA SA 25.1

- AUMA SA 30.1

- AUMA SA 35.1

- AUMA SA 40.1

- AUMA SA 48.1

The advantages of these electric drives include:

- Commissioning and diagnostics are possible via the CDT software. The communication between the digital interfaces, the laptop and the drive is based on a Bluetooth connection.

- Installation is very simple. Plug-in couplings allow for easy adaptation between actuator and valve; The electrical connection is made via the terminal connector.

- The DCS can be controlled either with the OPEN-STOP-CLOSE control commands or by defining a setpoint. Commands and feedback signals are transmitted either through conventional parallel interfaces or through network interfaces.

- AUMA actuators support protocols field bus.

Actuators and control units from AUMA SA are used in process plants all over the world to ensure a continuous production process. This equipment is used in various industries and has a long service life.

The second generation drives meet the highest requirements for the automation of modern process plants in the field of oil and gas equipment. In addition to standard units, parts can be made to order.

The second generation actuators are compatible with previous AUMA actuators. Drives and control units of different generations can be operated together.

The modular principle allows you to combine AUMA multi-turn actuators SAEx with control units manufacturing equipment according to customer specifications.

A large number of options are available in terms of housing options, temperature ranges, wiring diagrams, applicable types of microswitches, as well as combinations with control units and reduction gears

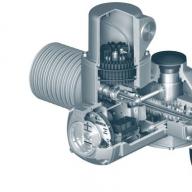

Electric actuators AUMA SA.Sectional image.

AUMA electric actuators are distinguished by such indicators as:

- Compatibility. Generation 2 actuators are compatible with previous AUMA actuators. All control and configuration settings are shown on the large display.

- Convenience. The advanced flywheel design makes it easy to activate manual control and drive the drive with only a little effort with one hand.

- Control precision. A more advanced mechanical design has improved the control accuracy and increased the output rotation speed for modulating drives.

- Long service life. The materials used, the design principle and new manufacturing techniques, as well as increased corrosion protection, ensure a longer service life of the equipment.

- Ease of adaptation. The universal hollow shaft of the second generation actuators allows connection with any type of valve.

- Safety. The operator of the equipment is alerted to a situation that could lead to failure. In the event of a fault, emergency operation allows the actuators to be moved to preset positions.

- Ease of integration. AMExC control unit provides communication on all standard digital protocols, including Profibus DP-V2, and allows you to quickly and easily integrate the device into the DCS, such as FDT/DTM.

Electric actuators AUMA SA.Technical specifications

| Type | Speed | Setting range | Flange for fittings | |

| rpm | Nm | EN ISO 5210 | DIN 3210 | |

| SA 07.2 | 4 -180 | 10 – 30 | F07 or F10 | GO |

| SA 07.6 | 4 -180 | 20 – 60 | F07 or F10 | GO |

| SA 10.2 | 4 -180 | 40 – 120 | F10 | GO |

| SA 14.2 | 4 -180 | 100 – 250 | F14 | G1/2 |

| SA 14.6 | 4 -180 | 200 – 500 | F14 | G1/2 |

| SA 16.2 | 4 -180 | 400 – 1 000 | F16 | G3 |

| SA 25.1 | 4- 90 | 630 – 2 000 | F25 | G4 |

| SA 30.1 | 4- 90 | 1 250 – 4 000 | F30 | G5 |

| SA 35.1 | 4- 45 | 2 500 – 8 000 | F35 | G6 |

| SA 40.1 | 4- 32 | 5 000 – 16 000 | F40 | G7 |

| SA 48.1 | 4- 16 | 10 000 – 32 000 | F48 | - |

Multi-turn actuator AUMA SA Design features:

Working mode:

- short-term S 2 - 15 min.

- repeated-short-term S 4 - 25%.

Self-braking:

- at speeds up to 90 rpm. (50 Hz)

- 108 rpm (60 Hz).

Electric motor:

- three-phase asynchronous, version IM B9 according to IEC 60034.

Insulation class:

- F, tropicalized - standard

- H, tropical version - option.

Motor protection:

- thermal switches (NC) - standard

- thermistors (PTC according to DIN 44082) - option.

Degree of protection:

- IP 68 - standard.

Corrosion protection:

- KS - standard

- KX, KX-G - option.

Automation:

- control units Auma MATIC, AUMATIC - option.

Technical data:

- Electric drive type: multiturn.

- Control mode: open close.

- Execution type: general industrial.

- Model: NORM.

- Working mode: short-term.

- Temperature range (C˚): -40...+80.

- Torque (Nm): 10 - 1000.

- Cr. adjusting torque (Nm): 30.

- Rotation speed (rpm): 4 - 180*.

- Electric motor: 3-phase asynchronous, version IM B9 according to IEC 60034.

- Power ~ (B): 220 - 500 V, 50 - 60 Hz.

- Protection class: IP68.

- Automated fittings: Gate valves, Gate valves.

Designation and marking of electric drives

Other AUMA actuators presented in our catalog.

Next page | Previous page |

| |

This article provides an overview of functions and applications for SA multi-turn actuators manufactured by AUMA as well as control units. The article can be useful to both an expert and a non-specialist in selecting a device for a given application.

For AUMA multi-turn actuators operating in the Open-Close mode, the designation SA is accepted: (Electric actuators AUMA SA 07.2 – SA 48.1) AUMA multi-turn actuators operating in modulating mode are designated SAR: ( Actuators AUMA SAR 07.2 – SAR 30.1)

SA multi-turn actuators develop torques from 10 Nm to 32,000 Nm. Combination with GS part-turn gearboxes provides torque up to 675,000 Nm. Such a wide range allows automation of fittings of any diameters and pressure levels. Management is carried out through a distributed control system (DCS), according to a standard scheme.

Second generation actuators are compatible with AUMA actuators previous versions. Drives and control units of different generations can be operated together. This provides investment security and allows the introduction of new, more advanced technologies.

Electric actuators AUMA SA. Ease of operation

One of the main advantages of AUMA equipment is convenience. All control and configuration settings are shown on the large display. All devices have a convenient multilingual menu.

The control is carried out via the local control panel or using the AUMA Tool Suite wirelessly via a laptop or communicator.

AUMA controls continuously record and analyze key characteristics such as torque, temperature and vibration. Deviations from operating modes are recorded, as well as exceeding the limit values.

The operator of the equipment is alerted to a situation that could lead to failure. Thus, it is possible to take measures in advance and prevent a simple installation. All events and signals are classified according to NAMUR requirements. Settings, workflows, and errors are logged in an event report with a time stamp and can be reviewed at any time.

To the undoubted advantages of drivesAUMA also includes:

- Ease of integration. Parallel connection of digital inputs (up to 10) and output contacts (up to 12) provides a convenient interface for the DCS. Control units of type and provide connection to all standard digital protocols, including -V2, and allow quick and easy integration of the device into the DCS, such as FDT/DTM. The universal hollow shaft of the second generation actuators allows connection with any type of valve.

- Functioningatfallvoltage up to -30%

- Temperatureenvironmentalenvironmentsfrom–60 °Сup to +70°С

- Better management and operation.

- advanceddesignflywheel - makes it easy to activate manual control and drive the actuator with only a small amount of force with one hand. The command to activate manual control can be transmitted to the control room.

- Electricalconnection of the electric motor is the same for all drives of the second generation.

- Universalloweringreducer in the switch box covers the entire range of standard strokes.

- Control precision. A more advanced mechanical design with a significantly reduced mechanical error has improved the control accuracy and increased the output rotational speed for modulating drives.

- Long service life. The materials used, the design principle and new manufacturing techniques, as well as increased corrosion protection, ensure a longer service life of the equipment.

AUMA equipment. Concern for the safety of personnel.

AUMA equipment is used all over the world – in all climatic zones and in all industrial plants. The main requirements that any technical device must meet include its uninterrupted and long-term operation under conditions of minimal maintenance.

AUMA equipment is used all over the world – in all climatic zones and in all industrial plants. The main requirements that any technical device must meet include its uninterrupted and long-term operation under conditions of minimal maintenance.

For this reason, AUMA's main focus is to use state-of-the-art technology to develop and manufacture devices that are resistant to extremely harsh operating conditions.

- High protection classes. AUMA devices of the second generation are manufactured with protection class IP68 in accordance with EN 60529. They provide up to 96 hours of submersion at a depth of 8 meters. In the submerged position, up to 10 switchings are allowed. In order to comply with protection class IP 68, the appropriate cable glands must be used. These connectors are not included in the standard delivery package, but they can be purchased separately.

- Corrosion protection performance is a key factor in determining the life of the equipment. The protective layer is applied in two stages: preliminary chemical surface treatment and powder application in two layers. According to the corrosiveness categories according to EN ISO 12944-2, different levels of protection are distinguished for the respective application.

- Valve overload protection. In the event of an increase in torque due to, for example, a foreign object on the valve stem, the actuator will trip to prevent damage to the valve.

- Thermal motor protection. If the temperature in the motor exceeds 140 °C, a thermal switch or thermistor will trip in the motor winding. They optimally protect the motor winding from overheating. Thermal switches or PTC thermistors provide a higher degree of protection than thermal overload relays because the temperature is measured directly on the motor windings.

- block duplication technology. To increase reliability, redundant bus blocks are used, as well as combined interfaces with parallel communication in the bus line. In the event of a fault, emergency mode allows the actuators to be moved to preset positions.

- Direction of rotation correction. Automatic correction of the direction of rotation in the event of a wrong phase sequence is an integral function of the control units. If the phases are reversed when the three-phase power supply is connected, the drive continues to move in the correct direction when the corresponding control command is received.

- Armature overload protection. The control unit disables the drive if the torque is exceeded during the stroke.

- Blocking of manual control. The handwheel and the electric motor cannot be blocked at the same time, thus avoiding the control error. Motor control is the priority. Activating manual control while the motor is running does not cause a malfunction or damage to the equipment.

- Actuator operation on loss of signal or in an emergency. If the control signal is lost or if an alarm is activated, the drive continues to operate in the predefined alarm mode. In the event of such a situation, it is possible to disable the protective mechanisms on the drive.

- Protective tube for rising valve stem. The protective tube, available as an option, protects the rising valve stem from contamination and protects the operator from injury.

- Handwheel extension. For drives installed in inconvenient places (mines, etc.), access to the flywheel is difficult. For such cases, a handwheel extension is available to facilitate manual handling.

- Wall mount. If access to the drive is restricted, if vibrations are excessive or if the ambient temperature is too high, the control box must be mounted separately from the drive on a wall bracket. The cable length between the drive and the control unit can be up to 100 m. The wall bracket can be upgraded at any time.

- Optimal equipment position. The position of the devices can be easily selected and adjusted, which solves problems such as incorrect positioning of the display, difficulty in accessing controls, cable glands, etc. Position changes in 90° increments are possible in the following cases: control unit to the actuator, control panel on the control unit, and terminal connector to the control unit. Thanks to the removable terminal connectors, the installation position can be quickly and easily changed on site.

For the user, three parameters are key: long service life, minimum maintenance with a long interval and maintainability. These characteristics inevitably affect the operating cost estimate and are therefore clearly monitored by the operator.

AUMA actuators can be integrated into any automation system. However, a more convenient and cost-effective option is to install a control unit on the drive. In addition, this will greatly simplify the process of putting the equipment into operation. Actuators with an integrated control unit are already ready for operation, because the control unit is fully functionally compatible with the drive. Once the power supply has been connected, the drive can be controlled using the pushbuttons on the local controls.

The drive can be installed on site, without direct connection to the DCS. Only control commands and feedback signals are still transmitted from the control system to the drive and vice versa. Any switching of the operating mode of the electric motor is carried out by the device itself and without delay. AUMA actuators can be supplied in combination with an AM or AC control unit. Both types of control unit differ in their functions.

Digital interfacesAUMA.

Connection systems according to field bus are used to transmit any signals received from various devices. Conventional systems require the use of switch cabinets with I/O units, while only one interface is sufficient for a field bus.

Connection systems according to field bus are used to transmit any signals received from various devices. Conventional systems require the use of switch cabinets with I/O units, while only one interface is sufficient for a field bus.

The digitization of all data allowed to expand the functionality of the system, for example, configure a field device through the DCS or receive all information about the device from the control room. AUMA actuators with integrated control units can be connected to all standard fieldbus communication systems within process automation.

The built-in control units process the drive signals and control commands and execute the required switching commands automatically and without delay using gearboxes, reversing contactors or thyristors. Control units transmit the processed signals from the drives to the higher level system. The drive can be easily operated on the jobsite using local controls. Blocks and are compatible with all generations of AUMA actuators. DCS is able to unify and process information from actuators and valves of any type.

Possibilities of digital monitoring.

- Integration of monitoring and diagnostic capabilities to facilitate regular maintenance by the operator. These functions allow drives to provide information about their own status, the range of signals provided far exceeds the number of standard error signals. The operator receives all information about the possible occurrence of errors in a timely manner via the NAMUR classification signal "Out of specification". This signal indicates that the operating conditions of the drive are not as specified and may result in an error. In this case, preventive measures must be taken.

- Diagnostic Information - Troubleshooting. While the operator only receives simple NAMUR signals, detailed actuator status diagnostic information is provided to the service engineer either via the display or the Tool Suite. In this way, the source of the "Maintenance Required" signal can be identified and appropriate action taken.

- Service life monitoring. In addition to valve torque requirements and duty cycles, device vibration and temperature are key determinants of equipment life. As an option, actuators can be equipped with sensors to continuously monitor the temperature of the motor, gearbox and electronics.

- Event report with time stamp and operating data logging. Setup procedures, enable-disable, warnings, errors and running time are recorded in the event report. This function is an important diagnostic tool for speakers.

- torque characteristics. The AC control unit registers the torque characteristics at different time intervals. Comparing the current curve with the reference one, we can draw a conclusion about the state of the reinforcement.

- Equipment management system. AUMA actuators with built-in control unit AC 01.2 meet all requirements for integration into such systems thanks to their extensive diagnostics and classification of status signals according to NAMUR.

Electric drivesAUMA. Quality and reliability.

The main requirement that drives must meet is reliability. It is the drives that determine the course of a well-coordinated technological process. Reliability first of all means thoughtful design, careful selection of materials, as well as the use of the most modern production technologies within a well-coordinated technological process.