One of the leaders in the world market for the production and development of new types of heat exchange equipment for various purposes is the Swedish company Alfa Laval Lund AB. Founded in 1883, it successfully operates today.

Alfa Laval heat exchangers of 2 types have won the greatest popularity in the markets: Alfa Laval heat exchanger is collapsible and brazed. Each of these types has certain advantages that make their use in a particular case more rational.

The main activity of the company is devices that provide separation (separation), heating, cooling, transportation of various liquid substances, including chemical reagents, petroleum products, medicines and food liquids, bulk mixtures - these are heat exchangers. This is a large international company that has a number of patents for unique PHE designs used in heat exchange equipment of plates, frames, gaskets, has know-how in the field of technological solutions and uses only high quality materials in its activities, which ensures a decent level of end products, its long service life and reliability.

Today, the need for such devices is quite wide and they are used in many countries of the world in the field of centralized water supply, which includes the supply, including hot water, as well as in air conditioning and the creation of ventilation systems for buildings and structures. Steam or water acts as a heating medium.

Alfa Laval heat exchangers - key benefits

- In PHE, plates with a thickness of 0.5 mm are used and they are made by one-way extrusion. Thanks to this production method and the special profile of the flow channels, stiffness and strength of the structure, a long service life, efficient heat transfer and reliability are achieved;

- The number of possible leaks is minimized due to the precise placement of the plates, which is ensured by the special frame design. This allows for multiple disassembly and assembly, as well as changing its area by removing or adding additional plates;

- The possibility of repeated cycles of disassembling and assembling the PHE is achieved by using seamless gaskets, the fixation of which is not based on the use of adhesives. In addition, the profile of the gasket is a patented technical solution, since it is he who is responsible for the tightness of the working space and, due to this, the long life of the gasket.

A heat exchanger is a unit in which heat is transferred from a working environment with a high temperature to the final heat consumer - a cold environment with the assistance of corrugated plates sandwiched between two powerful panels that hold them together. In some cases, this may not be a collapsible heat exchanger with an area of 0.2 sq.m., in others, collapsible units, the performance of which, if desired, can be increased.

Service maintenance of devices

You can also order service from us for equipment purchased from us, or for equipment already installed at your enterprise, TsTP or ITP. The list of services we offer includes the following:

- Flushing, repair, maintenance

- Replacement of plates, gaskets in heat exchangers, increase in power

- Delivery and installation, preventive maintenance.

Gaskets and plates

In the "Warm Company" you can also purchase a complete set of spare parts for heat exchangers and various other equipment. Any supplied heat exchanger, as well as spare parts (plates or seals) of high quality. The status of an official partner allows you to guarantee 100% that the heat exchanger meets all the declared characteristics. Spare parts, in turn, are also official.

- Gaskets for Alfa Laval heat exchangers

- Alfa Laval seals for heat exchanger

- Spare new plates Alfa Laval

- Alfa Laval cleaners, flushes and reagents for all heat exchangers

Register your heat exchangers and get an additional discount on service and spare parts!

Benefits of registering Alfa Laval:

- Discount on the purchase of components for Alfa Laval PTOs working in heat supply and air conditioning

- Additional year warranty for all heat exchangers

- Service from an authorized service partner in the region

- Supply of original components for the heat exchanger

- Service Schedule

- Equipment Maintenance Instructions

- Recover passport data and check the heat exchanger online.

Spiral devices - the main advantages

Spirals are most often used in the treatment of liquids containing solid particles, sediments of various compositions, as well as sludge, suspensions and viscous liquids. Small devices can also be used successfully in wastewater treatment.

A modern spiral type heat exchanger is that in their design they resemble a clock spring, which consists of two metal sheets twisted to form channels. In this case, the liquids that pass through these channels do not mix, but at the same time, high quality heat transfer and the most suitable parameters of flows that differ in viscosity, composition and intensity are ensured. Since the channels have a concentric design, they do not require a lot of space for installation, which saves a lot of usable area that can be used for production purposes.

Heat exchanger - principle of operation

Collapsible sink PTO

If the bath has a high-quality stove, then a boiler will not be required to heat the liquid that will flow into the washing room. An Alfa Laval heat exchanger can be used for this. Its main function is to heat the incoming liquid and return it to the mounted tank. That is why, while the "heart" of the bath is burning, the water in the adjacent room will remain hot. After the bath stops heating, the water is drained. This is precisely the rationality of this idea.

Specifications of the heat exchanger

If you are interested in the Alfa Laval manufacturer, you can select a heat exchanger from this supplier. How exactly will be described below. Bath stoves equipped with a heat exchanger are structures in which there is a space where cold water enters. After its temperature rises, it begins to move through the pipes, moving towards the hanging tank or radiators. At the same time, the role of the heat exchanger of the bath stove is not only to heat the liquid for the shower, but also to remote tanks located in the rest room or dressing room.

Varieties

If you are interested in the Alfa Laval heat exchanger, then you should consider that there are two versions of this design. Thus, the heat exchanger can be internal or external. In the first case, the device is a coil, which is launched along the bottom or built into the side of the furnace chamber. The coil is also called a shirt, which completely covers the firebox. If we are talking about an external heat exchanger, it is a chimney module, or rather a pipe, which is surrounded by a sealed container.

Key Features

The Alfa Laval heat exchanger, whatever type it may be, is filled with a liquid, which can be water or antifreeze. The reporting tank is responsible for supplying liquid to the heat exchanger. Capacity is a hinged tank or a water heating battery. For connection, as a rule, two fittings are used, one of them is located below, while the other is located on top. The principle of operation of the heat exchanger is extremely simple, everything happens due to the circulation of heated water or by connecting a pump that must be powered by electricity.

Alfa Laval brazed heat exchangers are commercially available in a wide range. Experts recommend choosing open systems for heating the coolant in the bath, while the process will not be accompanied by pressure. It is also important that the most efficient system for heating the liquid in the bath is the one whose total length of pipes does not exceed 3 meters. As practice shows, this will be enough to place the tank directly behind the wall of the steam room. It is important to pay attention to the thickness of the pipe, it is better if it turns out to be less than an inch, otherwise there will be considerable resistance to the movement of water, while a sauna stove with a heat exchanger, devoid of a pump, will not have the ability to distill water. If you have considered the Alfa Laval heat exchanger and decided to make such a unit yourself, then you should be guided by the advice of experienced craftsmen. They recommend making this design using old radiators, which is true if suitable materials were not at hand. You can use car radiators or borrowed from the heating system. They will need to be combined, which will increase the heat exchange area. In the course of the work, the use of adapters will be required.

Calculation of heat exchanger area

Experts emphasize that the calculations of the dimensions of the heat exchanger, as a rule, are the same. For example, it will take about 5 kW to heat a traditional room, this is the amount of energy that a furnace with a heat exchanger should produce. With regard to one square meter of heat exchanger area, this will be approximately 9 kW during the combustion. Undoubtedly, much will depend on the location of the boiler with the furnace, as well as the intensity of fuel combustion. However, the power of the boiler after the completion of the combustion process will drop by 10 times. That is why the surface area of the heat exchanger must be calculated with some margin, only in this way you will be able to create a system that will be able to maintain a comfortable temperature in all rooms of the bath complex with a two-time or one-time firebox. Considering the Alfa Laval plate heat exchanger, you should take into account that the shape of the boiler and furnace can be very different. However, the most popular are those made of stainless pipes, however, those made of two channels are becoming more common.

Characteristics of the Alfa Laval M3 heat exchanger

If you have paid attention to the Alfa Laval plate heat exchanger, then before purchasing it is worth considering in more detail the technical characteristics. If we are talking about the above model, then it will be 3.9 cubic meters. The plates of this variant of the heat exchanger have a surface area of 0.08 square meters. As for the maximum heat exchange area, it is equivalent to 3.9 square meters. The described model is small in size and very convenient to use, also quite compact design, it includes a frame that can withstand a maximum pressure of 16 bar. Among other things, the device is equipped with a plate. This model acts as a standard version of a gasketed plate heat exchanger, which consists of several plates. Frames are located on both sides. During the production process, the plates are given a corrugated surface, which makes it possible to provide high-quality heat supply by transferring fluid that is in countercurrent to each other. In order to prevent water from flowing into one another and from flowing out of the structure, the latter has a number of seals and gaskets that are designed to protect the internal contents from the effects of the external environment.

POSITIVE FEATURES Alfa Laval M3

Alfa Laval heat exchangers, whose characteristics it will be useful for you to read before visiting the store, are a quality product that allows heating equipment to work efficiently. The unit of this series is also called a water heater because of the functions it performs. If we consider in more detail the technical characteristics of a heat exchanger of this kind, then some dimensions can be distinguished. Namely, the height of the unit, which is 480 millimeters, the width (180 millimeters) and the maximum temperature, equal to 180 degrees. The fluid flow is 4 kilograms per second.

The Alfa Laval heat exchanger, the technical characteristics of which will be of interest to every consumer, is presented in a single-pass design, the design does not have a support heel, which is also called legs. This model is necessarily supplemented with the necessary one - a passport and an instruction manual. Documents will be required so that users have an idea about the features of the equipment and are able to cope with problems encountered during operation. After all, the buyer will certainly have to maintain, carry out preventive work, clean the system, which will help the efficient operation of the device. After the calculation of Alfa Laval heat exchangers has been made, you can go to the store. Only in this way can you create a system that will have a high efficiency.

Conclusion

It is advisable to purchase the model of the heat exchanger that is recommended by the manufacturer. This will ensure that the design is suitable for a particular installation, and during operation you will not encounter failures.

Among the leading companies in Sweden today there are not so many veterans who created the once glory of the Swedish industry. One of them, without a doubt, is an international industrial concern Alfa Laval.

Today Alfa Laval- one of the largest international industrial groups, which includes more than 110 marketing companies and representative offices in 95 countries. The production potential of the company is 40 factories and dozens of auxiliary industries. Scientific developments are carried out in 20 research centers. More than 10,000 employees around the world work to create the very base on which Alfa Laval's weight, authority, experience and global recognition rest.

Alfa Laval- one of the oldest foreign firms in the Russian market, its representative office in St. Petersburg opened in 1905.

OJSC Alfa Laval Potok represents the interests of the Alfa Laval concern in Russia, ensuring the production of certain types of products, as well as the sale of the entire range of equipment manufactured at the enterprises of the concern around the world: plate heat exchangers, separators, condensers, desalters, decanters, filtration equipment, shut-off and control valves for flow-conducting equipment. In addition, the company provides a full range of services for maintenance, equipment repair and staff training.

Alfa Laval heat exchangers are designs that are designed for modern cold stores, heating and hot water circuits, ventilation and air conditioning systems. For more than a century, Alfa Laval heat exchangers from Sweden have been distinguished by the highest quality of production.

Alfa Laval company logo

About company

Alfa Laval, founded in 1883, is now a leader in the manufacture of high quality heat transfer products in more than one hundred countries worldwide.

You can find out the price and buy heating equipment and related products from us. Write, call and come to one of the stores in your city. Delivery across all territory of the Russian Federation and the CIS countries.

In Russia, the company has been known since 1992, when it launched its production of heat exchangers in one of the cities of the Moscow region on the basis of a former machine-building plant.

The main direction of the company is the improvement of energy-efficient technologies. The range of this company includes many different units, based on the Alfa Laval plate heat exchanger.

Externally, Alfa Laval plate heat exchangers do not differ from each other. Features only in the design of the plates and sealing material. The manufacturer has developed unique production technologies and designs of heat exchangers. Let's take the following:

- One-step pressing of plates. As a result, it became possible to obtain a homogeneous material of the plates and to increase the level of heat transfer.

- Special shape of the distribution surface. It makes it possible to rationally use the entire area of the plates of heat exchange equipment and make it less polluted.

Alfa Laval plate heat exchangers

Alfa Laval plate heat exchangers are quite common in Russia and are used by European and Russian manufacturers of refrigeration units as evaporators, condensers, superheated vapor coolers, economizers heat exchange equipment and liquid / liquid structures between two coolants, etc.

The main advantages of plate-type heat exchangers can be distinguished as follows:

- High level of heat transfer. It is achieved due to high turbulence during the circulation of the water flow inside the heat exchanger plates.

- Small mass of refrigerant, which is in the heat exchange equipment at the time of operation. This provides a low refrigerant charge for a chiller that uses an evaporator or condenser as a plate heat exchanger.

- Compactness when compared with other types of heat exchange equipment. Small dimensions allow the refrigeration unit as a whole to have a significantly less weight.

The company has launched the production of two main types of plate-type heat exchangers:

- Lamellar collapsible (this includes lamellar collapsible-welded).

- Alfa Laval brazed copper plate heat exchangers.

Alfa Laval copper-brazed heat exchangers, however, are divided into the "CB" and "AC" series.

| Brazed copper heat exchanger series | Peculiarities |

|---|---|

| Series "SV" | This is an Alfa Laval brazed heat exchanger used in refrigeration applications as condensers and liquid/liquid heat exchangers. Often they are also used as superheated vapor coolers for water heating using heat removed from the hot vapors of the refrigeration unit discharge. Customers always have access to heat exchangers CB27, CB52, CB76 with the number of plates from 10 to 100. |

| Series "AS" | The series is used in refrigeration units as evaporators. The main feature is the presence of a liquid distributor at the inlet of the refrigerant circuit, which makes it possible to evenly distribute the mixture of vapor and liquid between the plates (the mixture is formed as a result of expansion of the liquid refrigerant in the thermostatic valve). Customers always have access to heat exchangers AC10, AC30, AC70, AC120, AC250 with the number of plates from 14 to 120. |

Plate heat exchanger Alfa Laval T5-MFG

The Alfa Laval T5 MFG heat exchanger is popular, designed for use in almost all industrial sectors with the need to heat or cool various liquids. Often the equipment is used in heating systems and hot supply systems, where ease of installation, low operating costs and high energy efficiency are important.

The combination of all these properties makes the Alfa Laval t5 mfg heat exchanger known as the best price / quality ratio in the Russian market, among competitors in terms of type and size.

Specifications for the Alfa Laval T5 MFG plate heat exchanger.

| Characteristic | Meaning |

|---|---|

| Manufacturer country | Sweden |

| Model | T5 |

| frame type | FG |

| Connection diameters, mm | 50 |

| Connection type | flange , thread |

| Height, mm | 737 |

| Minimum standard length L, mm | 190 |

| Maximum standard length L, mm | 365 |

| Maximum fluid flow, kg/s | 5 |

| Horizontal distance between ports HC, mm | 100 |

| Vertical distance between ports VC, mm | 553 |

| Width, mm | 245 |

| Maximum pressure, bar | 16 |

| Max. operating temperature, °C | 180 |

| PV codes and directives | ALS, PED, ASME |

| Type of heat exchanger | T5-MFG |

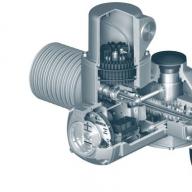

Shell and tube heat exchanger Alfa Laval

Alfa Laval types are used for heating and cooling processes of a heat carrier (water, steam, gas, oil, oil, acid, alkaline, etc.).

Tubes of conventional materials or special profiles with high resistance to temperature and chemical effects are placed inside the casing. One heat carrier circulates inside the pipes, and the second - inside the casing.

Shell and tube condensers and evaporators are excellent for industrial refrigeration, air conditioning, industrial and ocean water heating applications.

Alfa Laval shell and tube product options: DH, DM, Pure Cooler, Dryplus-3, FEV-HP, CDEW and CDEW-E, CRF, CXP, CXPM, McDEW, Cetecoil.

Characteristics of Alfa Laval shell and tube heat exchangers.

| Shell and tube heat exchanger series | Peculiarities |

|---|---|

| D.H. | These are one-, two-, three- and four-pass heat exchangers for cooling processes with temperature evaporation from 0 to +10 °C. |

| DM | This includes a series of evaporators designed for refrigeration systems with an evaporating temperature range of -10 to -20 °C. |

| Pure Cooler | It is a single-pass evaporator for refrigeration systems (0 to +10 °C.). |

| Dryplus-3 | Evaporators widely used as chillers in ventilation systems, brine cooling, process cooling systems and heat pumps. |

| FEV HP | This is a flooded evaporator that is installed in ventilation and cooling systems. |

| CDEW and CDEW-E | They are used for systems in which cooling water is obtained from rivers, lakes, wells and other secondary production processes. |

| CRF | Made from freon R407C/F and R134a. |

| CXP | They operate on R404 refrigerant. |

| CXPM | Used for sea water systems using HCFC or HFC refrigerants at medium and high pressure (30-45 bar). |

| McDEW | Manufactured for marine environments (HCFC refrigerants at 30-45 bar). |

| Cetecoil | It is intended for processes with a high speed of the movement of working environments. For example, when working with steam, they are quite effective condensate coolers. |

Alfa Laval is a Swedish manufacturer and remains a leader in the manufacture and development of industrial heat exchange equipment of varying complexity.

Alfa Laval Swedish heat exchangers definitely deserve your attention and consideration!

"Alfa Laval" (Alfa Laval) is one of the oldest foreign firms on the Russian market, its representative office in St. Petersburg opened in 1905.

ALFA LAVAL in Russia

Alfa Laval is one of the first foreign companies to start its own production in Russia. It was founded in 1992 on the basis of the Bolshevsky Machine-Building Plant (Korolev, Moscow Region), which specialized in the production of pasteurization and cooling units.

The total amount of capital investments in the reconstruction of the plant amounted to more than 20 million dollars. In 1996, the commercial division and the plant merged under one name - OJSC Alfa Laval Potok.

The basis of the production program of the plant is plate heat exchangers of various capacities, which are produced according to Alfa Laval technology (Alfa Laval) for many industries and heat supply systems for urban utilities.

OJSC Alfa Laval Potok represents the interests of the Alfa Lava concern in Russia, ensuring the production of certain types of products, as well as the sale of the entire range of equipment manufactured at the enterprises of the concern around the world: plate heat exchangers, separators, condensers, desalters, decanters, filtration equipment, shut-off and control valves for flow-conducting equipment. In addition, the company provides a full range of services for maintenance, equipment repair and staff training.

Gasketed plate heat exchangers of the M and TS series form the basis of the production program of the Alfa Laval Potok plant, which operate in many industries and municipal heating systems. We produced the first heat exchanger in 1995, the 10,000th in 2001, and the 20,000th in 2004. That is, over the past three years, the volume of production has doubled. The plant also produces rubber seals, which are important components of heat exchangers. We produce 160,000 seals per year in a variety of rubber formulations developed in Alfa Laval's Swedish R&D laboratories. JSC Alfa Laval Potok is certified for compliance with the requirements of the international quality system ISO 9001-2000. On all equipment there are certificates of conformity of Gosstandart.

About ALFA LAVAL

The international industrial concern Alfa Laval is the world's largest manufacturer of equipment and technologies that help optimize production processes and dramatically increase their returns.

Working closely with its partners in nearly 100 countries around the world, Alfa Laval helps them to remain leaders in their industries.

Alfa Laval has a wide range of heat exchangers and can offer the customer the best solution tailored to his specific requirements. Alfa Laval welded plate heat exchangers are capable of operating at extremely high pressures. Unpretentious in operation, semi-welded and compact brazed heat exchangers are widely used for heating and cooling. Shell and tube heat exchangers like evaporators and condensers are the best for refrigeration systems.