As an additional and alternative source of energy, solar panels are actively used not only in industrial but also in domestic conditions. But before installing such a source of electricity for himself, it is important for the buyer to find out how to choose the solar panels that are optimal in terms of characteristics and power for the home, because the price of ready-made kits varies in a fairly wide range.

The use of solar panels in the middle lane - it is also possible to use free energy here

Where are solar panels most commonly used?

The field of application of solar panels is huge. Already now they are successfully used for power supply of private and apartment buildings, farms, including for lighting and heating greenhouses, buildings, lighting of the local area, powering devices.

Most often, they think about autonomous power supply in the following cases:

If the area is not electrified, solar panels for a private home will be much cheaper than using liquid fuel generators.

In rural areas, electricity is often cut off, and people are literally left without electricity. By turning on the autonomous power supply, you can live in the usual comfort long time, especially since a battery is always included with solar panels.

In apartment buildings, solar modules are also used as backup, and there are projects that involve the use of solar energy for hot water supply.

As a rule, in documents for equipment, a shelf life of 20 to 25 or even 30 years is indicated. However, many devices continue to function after the period specified by the manufacturers. For example, the world's first solar battery has been operating for over 60 years, and over the years, the production technology has been significantly improved.

The prototype of the solar battery was developed at the end of the 19th century.

Obviously, only one drawback can be singled out - with constant operation, the capacity of the equipment decreases, nevertheless, these indicators are insignificant: for 10 years, no more than 10%.

Prevent physical damage such as falling trees, being blown off by wind and scratching sensing elements. The efficiency of the device depends on the latter.

Carry out regular maintenance: maintenance and cleaning.

Install wind barriers if necessary.

In addition to the modules, the system includes the following components: batteries and power electronics. The service life of the first devices is from 2 to 15 years, the second - from 5 to 20 years, depending on the characteristics, intensity of use and careful maintenance.

General characteristics and availability of purchase

The equipment is not harmful to the environment and provides a stable power supply without voltage surges. And, most importantly, it supplies free energy: for which utility bills do not come.

The appearance of solar panels has changed little after their invention, which cannot be said about the internal "filling"

The solar module converts light into electrical energy generating D.C.... The area of the panels can be up to several meters. When it is necessary to increase the capacity of the system, the number of modules is increased. Their effectiveness depends on the intensity of sunlight and the angle of incidence of the rays: on the location, season, climatic conditions and time of day. In order to correctly take into account all these nuances, the installation must be performed by professionals.

Monocrystalline. They consist of silicone cells that convert solar energy. They are distinguished by their compact size. In terms of their performance, they are the most efficient (efficiency up to 22%), which affects their price - this is the most expensive type of solar panels.

Polycrystalline. They use polycrystalline silicon. They are not as efficient (up to 18% efficiency) as monocrystalline solar cells. But their cost is significantly lower, so they are available to the general public.

Amorphous. They have silicon-based thin-film solar cells. They are inferior to mono and polycrystals in terms of energy production, but they are also cheaper. Their advantage is the ability to function in diffuse and even low light.

Polycrystalline Solar Panel

The system also includes the following components:

An inverter that converts DC to AC.

Accumulator battery. It not only accumulates energy, but also neutralizes voltage drops when the light level changes.

Controller for battery charging voltage, charging mode, temperature and other parameters.

In stores, you can purchase both individual components and entire systems. In this case, the power of devices is determined based on specific needs.

Functioning, types of converters and their comparative energy efficiency

Converters or inverters are key components of solar panels. They transform the direct current generated by the module into an alternating voltage of 220 V, which is necessary for the operation of electrical devices. Inverters are available in capacities ranging from 250 to 8000 W. When buying, it is recommended to take into account the highest network load and correlate voltage and power. The following parameters are considered optimal: 12 volts and 600 watts, 24 volts at 600-1500 watts, 48 volts if the power is more than 1500 watts.

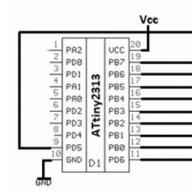

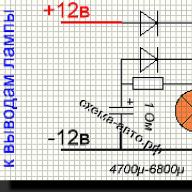

Inverter, on schematic diagram solar panels

Autonomous. Before choosing an inverter, you need to determine which devices will be powered from it, and calculate their total maximum power per unit of time. It is recommended to take the power of the inverter a little more. Some household electrical appliances, when turned on, create a sharp increase in voltage, due to which the device may fail.

Synchronous. They store energy, and the surplus is transferred to the electrical network. In the event of a shortage of electricity generated by the system, the converter will "borrow" it from the general network. The use of a synchronous model will avoid power outages.

Multifunctional devices have combined the advantages of the first and second types.

Depending on the shape of the output voltage signal, there are several types of converters that differ in application and cost:

With sinusoidal signal. They create a high quality current, which affects their cost. Large household appliances work from them: refrigerators, boilers, air conditioners.

Rectangular. Lighting fixtures are connected to these inexpensive inverters. Most household appliances are not compatible with them.

Pseudosinusoidal. Their advantage is the ability to connect almost all home appliances. But the signal quality is reduced compared to the first type, so they are cheaper.

The ribbed shape of the inverter is needed for the most efficient cooling

The cost of the kit and the main technical characteristics, payback period

Prices for ready-made kits generally range from 30,000 to 2,000,000 rubles. They depend on the devices that make them up (on the type of batteries, number of devices, manufacturer and characteristics). You can find budget options costing from 10,500 rubles. The economy kit includes a panel, a charge controller, a connector.

Standard kits include:

* Provided in extended configuration.

Standard set of equipment

Specifications indicate in the application manual:

The power and dimensions of the panels. The more power you need, the more profitable it is to buy larger batteries.

The temperature coefficient shows how much temperature affects power, voltage and current.

The principle of operation of a solar power plant at home

A solar power plant is a system consisting of panels, an inverter, a battery and a controller. A solar panel converts radiant energy into electricity (as mentioned above). Direct current flows into the controller, which distributes the current to consumers (for example, a computer or lighting). The inverter converts DC to AC and powers most electrical household appliances. The battery stores energy that can be consumed in the dark.

How solar energy is used to generate heat

Solar systems are used to heat water and heat the home. They can provide heat (at the request of the owner) even when the heating season is over, and provide the house hot water is free. The simplest device is a metal panel that is installed on the roof of a house. They store energy and heat the water that circulates through the pipes hidden underneath. The functioning of all solar systems is based on this principle, although they may be structurally different from each other.

Solar collectors consist of:

According to the type of design, flat and vacuum collectors are distinguished. In the former, the bottom is covered with heat-insulating material, and the liquid circulates through glass pipes. Vacuum collectors are highly efficient because heat losses in them are minimized. This type of collector provides not only solar heating of a private house - it is convenient to use for hot water supply systems and swimming pool heating.

How the solar collector works

The most common in Russia is the products of Chinese manufacturers, due to the relative cheapness compared to products manufactured in other countries. For example, solar panels from China are almost twice as cheap as German ones.

Most often, products from Yingli Green Energy and Suntech Power Co. are found on the shelves. HiminSolar panels (China) are also popular. Their solar panels generate electricity even in rainy weather.

The production of solar panels is also established by a domestic manufacturer. This is done by the following companies:

LLC "Hevel" in Novocheboksarsk;

Telecom-STV in Zelenograd;

Sun Shines (LLC Autonomous Lighting Systems) in Moscow;

JSC "Ryazan plant of cermet devices";

CJSC "Termotron-zavod" and others.

You can always find a suitable option at a cost. For example, in Moscow, you can order and buy ready-made sets of solar panels - at a price of 21,000 to 2,000,000 rubles. The cost depends on the configuration and power of the devices.

Solar panels are not always flat - there are a number of models that focus light at one point

Battery installation steps

To install the panels, the most illuminated place is chosen - most often these are the roofs and walls of buildings. For the device to function as efficiently as possible, the panels are mounted at a specific angle to the horizon. The level of darkness of the territory is also taken into account: surrounding objects that can create shadow (buildings, trees, etc.)

The panels are installed using special fastening systems.

Then the modules are connected to the battery, controller and inverter, and the entire system is adjusted.

For the efficient functioning of the equipment and a long service life, a correct installation is a prerequisite, which only experienced specialists can do.

Despite the complexity of connection and calibration, the work period is short - with the appropriate tools, competent installers will spend about half a day on everything.

For the installation of the system, a personal project is always developed, which takes into account all the features of the situation: how the installation of solar panels on the roof of the house will be carried out, the price and terms. Depending on the type and scope of work, all projects are calculated on an individual basis. The client accepts the work and receives a guarantee for it.

Installation of solar panels must be done by professionals and in compliance with safety measures

As a result - the prospects for the development of solar technologies

If on Earth the maximum effective work Since solar panels are disturbed by the air, which in a certain degree scatters the radiation of the Sun, then in space such a problem does not exist. Scientists are developing projects for giant orbiting satellites with solar panels that will operate 24 hours a day. From them, the energy will be transmitted to ground receiving devices. But this is a matter of the future, and for existing batteries, efforts are aimed at improving energy efficiency and reducing the size of devices.

Solar panels for home: characteristics, cost of the kit and installation

Solar panels for home: where are they used, what is the principle of operation, service life and General characteristics devices, equipment and cost of equipment.

Solar panels lifespan

A few years ago, there was no particular choice of modules from a Ukrainian manufacturer for a buyer. The price for solar modules from Ukrainian manufacturers was higher than for any imported modules.

Even now, the situation has not changed, but subsidies of the photovoltaic industry by the Chinese government have greatly improved the quality of solar cells and modules produced in China and reduced their prices. Now about 80% of solar cells on the world market are made in China or by Chinese manufacturers. Europe and the United States were so inundated with Chinese products that many local solar cell and module manufacturers were bankrupt. A number of solar cell and wafer manufacturers have gone bankrupt or shut down production. a similar situation for solar silicon producers. All over the world, the pressure from Chinese manufacturers is felt very strongly. So much so that the United States and the European Union have taken measures to restrict the import of Chinese-made PV modules into their domestic markets.

There are more and more Chinese and pseudo-European modules on the Ukrainian market. Unfortunately, not all Chinese modules are of acceptable quality. High-quality modules that meet all international standards are now being produced in China; the quality of such modules is better than currently produced in Ukraine. This has been made possible by the Chinese government's massive investment in solar energy.

Therefore, the buyer was faced with the question - how to distinguish good modules from bad ones? Why are some modules cheaper than others? What is the threat of the cheapness of the modules and will the buyer lose more in the future than he will save when buying?

Indeed, the answers to these questions are not obvious to the layman. All modules produce electricity by converting sunlight - so why buy more expensive? Here the situation can be compared with cars - you can get from point A to point B by different cars. Both can be of the same size and motor power. But one after a few kilometers will lose speed and will not be able to go fast, will begin to break down after every kilometer, etc. The other will travel all the way as it did at the beginning. As a result, on the first one, you risk not reaching your destination, while constantly repairing it, even cyclists will overtake you. Eventually, halfway through the journey, you will be forced to buy another car. In another, more expensive (and quality) car, you will reach the end without even noticing the path.

With solar panels, the situation is similar - it is almost impossible for a layman to determine if a module is good. The specifications will say that it delivers its nameplate power under standard test conditions. The look will be good too. The difference becomes noticeable after several years of operation. Also, different modules can work differently at illumination lower than 1000W / m2.

What to look for when choosing solar modules for your solar power system?

Price versus quality

In addition to the fact that not all manufacturers and solar modules are the same (this is discussed in the related article on the quality of solar cells), there are a number of parameters and factors that should be considered when making a purchase decision and when choosing a supplier. The price of the modules alone should not be the determining factor.

Problems and deterioration of the parameters of solar modules can be caused by the following factors:

- The quality of the solar cell - its efficiency varies. It depends on many of its parameters - shunt and series resistances, noise currents, return resistance, etc. Much depends on the quality of production of a solar cell and the quality of materials and equipment used in its production. Problems are known practically at every stage of cell production - from the quality of the silicon used to the quality of the applied contact pastes and solder. We will not consider these problems in this article, this is a subject for a separate large article.

- Soldering quality of solar cells. In case of poor-quality soldering, local overheating of the contact and its burnout are possible. It is better to choose modules in which the elements are soldered by a robot - in them the spread in the quality of soldering will be minimal

- The quality of the EVA film, which is located between the elements and the glass. Aging of crystalline solar modules is mainly associated with aging and cloudiness of this film. A poor-quality film can begin to grow cloudy and deteriorate after a few years. A good film will serve 30 or more years, while its haze (and, therefore, the loss of power by the module) will not exceed 25-30%

- The quality of the module sealing and the quality of the rear protective film. The back film protects the module from moisture. In any module, moisture diffusion occurs through the film. If the quality of the film is good, then all moisture that gets inside the module, when it is heated in the sun, is removed outside. If the film is of poor quality, then more moisture gets in than can be released when heated, residual moisture accumulates inside the modules and destroys the contacts and contact grid of the elements. This leads to premature failure of the module.

- The quality of the aluminum frame. Everything is clear here: poor-quality anodizing can lead to oxidation of the frame and its corrosion. Fortunately, this defect is more visual and hardly leads to premature module failure. Although, in some cases (for example, when installing modules on masts, where strong wind loads are possible or where the environment is aggressive), accelerated corrosion of the metal can lead to its destruction under loads.

How to determine what voltage the modules have?

In recent years, modules with non-standard voltages have appeared on the market, which are designed to work in series high-voltage circuits. WITH light hand non-professional sellers of solar panels - both Russian and Chinese - there was confusion about the nominal voltage of solar modules. We will give some tips on how to determine what voltage a solar panel has.

The voltage of a solar panel is determined by the number of solar cells connected in series. Each solar cell has an operating voltage of just under half a volt. Currently, there are modules with the number of elements 36.48, 54, 60.72 and 96. The most common modules with the number of elements 36, 60 and 72. At 48, 54 and 96 elements are much less common. The table below shows the main voltages of these solar panels.

1ТММ - point of maximum power

2 is due to the possibility of charging when connected to the battery directly or through a PWM controller. The rest of the modules can be used to charge batteries, but with the mandatory presence of an MPPT controller.

When purchasing modules for an autonomous system with batteries, pay attention to the voltage of the module. Recently, high-power modules (220-270 watts) with a non-standard voltage of about 20V have been mass-produced. These modules are usually used in conjunction with on-grid photovoltaic inverters or MPPT charge controllers. If you want to reduce the cost of the system at the expense of a less expensive PWM controller, choose modules with a nominal voltage of 12 V or 24 V.

Tolerance means the deviation of the real power of the module from the passport. Tolerance can be either positive or negative. For example, a 200W rated power module can have a power of 195W; this will mean that the given module has a negative tolerance. Positive tolerance means that the solar panel is not only guaranteed to have an output power of 200W under standard test conditions, but even more.

The temperature coefficient reflects how an increase or decrease in the temperature of the module will affect the output current and voltage of a module. As you know, the voltage and power of the module decrease with increasing temperature, and the current increases. The lower the temperature coefficient of change in power, the better.

Sunlight conversion efficiency

With this it is clear - the higher the efficiency, the smaller the area of the modules will be required to generate the same power and energy.

The total amount of energy expended in the manufacture of the module

Another parameter to look out for is the total amount of energy that could have been expended in the manufacture of a solar module - from mining silicon to shipping finished goods to the store. This parameter reflects how energy-intensive was the production of the module and how quickly the solar module will generate the same amount of energy that was spent on its production (the so-called energy payback).

The declared lifespan of a solar panel is important for several reasons. It can reflect the confidence of the manufacturer in the quality of the manufactured product. Reputable manufacturers have a 25-year warranty for 80-90% of the module's capacity, as well as 5 or more years for mechanical damage.

However, it must be borne in mind that the guarantee is valid as long as the manufacturer or importer exists. Here, "how the card will fall" - in recent years companies have left the solar business, which seemed to be in it for a very long time. But nevertheless, the general rule remains - buy from sellers and manufacturers who have been on the market for a long time and are steadily “floating” in the turbulent stream of the market. And this can only be done if there are professionals in the team (this is what we humbly hint at ourselves). Since few people buy modules directly from the manufacturer, it is important to choose the right vendor or installer to provide you with the right choices and modes of operation for your solar power system.

The cost of a module depends on its power in direct proportion. However, the higher the unit power of the module, the lower its cost per watt will be. Therefore, if you need a certain power, then it is better to collect it in large modules than in small ones - it will be both cheaper and more reliable, because you will have fewer connections. Also, the cost per watt of modules with a standard voltage of 12 / 24V (the number of cells in a module is 36 or 72) is usually higher than with a non-standard number of cells in a module 48, 54 or 60. For the latter, when charging the batteries, a more expensive MPPT controller is needed.

The type of solar cells used in a module also determines its size. Therefore, first calculate how much power you need to power your load, then see if you have enough space to accommodate so many modules. It may be necessary to select more expensive but more efficient modules in order to meet all your energy needs. Do not forget, by the way, that before designing a solar power supply system, you need to take all possible measures to save energy (this has already been written about on other pages of our site).

Peak power of all modules measured under standard test conditions:

Air mass AM = 1.5, radiation E = 1000 W / m2, and photovoltaic cell temperature Tc = 25 ° C. Such conditions do not exist during the actual operation of the modules - the modules usually heat up to 40-60 degrees, the illumination is almost always below 1000 W / m2 (with the exception of frosty clear days). Therefore, many manufacturers also give the characteristics of the module under NOCT (normal operation conditions) - usually for a module temperature of 45-47C and an illumination of 800 W / m2, while the output of the modules is about 25-30% lower than the peak. On a frosty clear day, the production of modules can reach up to 125% of the peak.

The type of solar cells is monocrystalline, polycrystalline, amorphous, etc.

The three main types of solar cells currently being marketed in large quantities (all silicon) are as follows:

- monocrystalline. Have the highest efficiency and satisfactory temperature coefficients

- polycrystalline. Currently, the most popular ones, as have a lower cost per watt with approximately the same characteristics as monocrystalline. Recent improvements in branded polycrystalline module technology have resulted in performance being even better than noname monocrystalline modules from panel manufacturers / assemblers.

- amorphous (thin-film). Use the smallest amount of silicon. They have approximately 2 times lower efficiency compared to crystalline modules. The advantages include low temperature coefficient (i.e., when heated, the power of such modules decreases slightly) and high sensitivity at low illumination.

Which modules, from the ones listed above, work better? Lately, there have been many myths and unsubstantiated claims that some of these module types perform better than others. Some claim that polycrystalline cells work better in low light and cloudy weather. Others claim the same, but for monocrystalline elements. I even heard a version that polycrystalline elements are better at transforming scattered light, because the crystals in them are “turned into different sides”.

Analysis of the results of testing hundreds of modules shows that the module is not good, which is mono or poly, but one that is made with high quality. The results of testing modules by PTC (which are closer to real conditions modules) show that some monocrystalline is better than some polycrystalline, and some polycrystalline is better than some monocrystalline. This fact is also confirmed by numerous results of comparisons of modules by end users - you can find both "proof" of the advantages of mono over poly, and the advantages of poly over mono. ...

How to choose the right photovoltaic panels made in China and not regret it?

The general rule is to choose solar cells and modules from large, well-known companies. These modules are made from the highest quality elements.

Cells that have not passed the rigorous selection of a brand manufacturer are sold to photovoltaic panel assemblers, of which there are many in China. Moreover, all these assemblers sell their OEM modules, i.e. under the trade names of other companies. There are most of them on the Russian market now. Always pay attention to the manufacturer indicated on the module sticker. The risk of getting modules of unknown quality, which will not know how to work, is very high, and if you do not even know the manufacturer (the trade name of the seller will not help you in any way in obtaining a guarantee), then be prepared that you are buying solar modules without a guarantee.

Usually cheap Chinese modules have the following disadvantages:

- Discrepancy between the declared power and the real

- Strong degradation of modules in the very first years of operation (up to 20-30%)

- Poor soldering and assembly quality

- The use of low-quality materials in the manufacture of the module (fluxes, film, aluminum, solar cells, etc.)

You can also buy modules at the online auction. But will they work as stated? Most likely not, and we have facts confirming this.

There is one more point to consider when buying imported modules - guarantee issue... There are no problems with Russian manufacturers in this regard - they all produce quick replacement or repair of modules under warranty. Responsible Russian importers, who have been on the market for many years, also provide their guarantee for the solar modules they import. Otherwise, you need to be very careful when choosing a solar panel supplier.

Modules with a sticker of trade brands without specifying the real manufacturer should make you wary - in most cases you will not be able to get warranty service for such modules, we have many examples of this.

Pay attention to how the modules are soldered. Small manufacturers solder the elements by hand, rather than by a robot, so the thickness of the solder changes when soldering the contact bars of the elements. Large firms solder with a robot, so the quality of soldering is much higher.

Be sure to find out how many years the module supplier has been on the market. Even if a Chinese manufacturer gives a guarantee for its products, think about how you will exchange the module - if your seller does not provide you with a guarantee, then practically you will not have it. If you directly contact a manufacturer in China, you will certainly incur the costs of transportation, customs clearance, etc. these costs are not covered by any foreign manufacturer. These costs can only be compensated for by a verified reliable seller who works in accordance with Russian law. If you buy modules from a well-known seller who has been working in this market for many years (for example, with us), you will also receive a guarantee for the modules from him. Beware of buying imported modules from installers or small sellers - they, in the vast majority of cases, cannot provide a warranty for the modules being sold. Always ask them for a manufacturer's or importer's warranty card, do not be too lazy to call the phone number indicated in the warranty card and ask who and how provides warranty service.

Therefore, our recommendation is to choose only branded photovoltaic modules, or at least those on which their manufacturer is indicated. Among the Chinese, these are TrinaSolar, Yingli, Canadian Solar, JA Solar, Suntech, Motech, Linuo, Hanwha, ReneSola, Jinko, etc. - read more here. They will really have a guarantee for many years, and not as long as the seller and his trademark exist.

If there is no manufacturer data on the module, but only the name of the OEM seller, this should alert you. Typically, these modules are made from low quality elements (Grade B and C) and at a low cost.

Solar modules are not cheap and are designed to last over 30 years. It would be very unwise to save 30-50% on the cost of a module and get a module that will not work in a few years, for which it is impossible to make claims to anyone. Remember that “cheap is never good”.

How to choose the right solar panels

General situation on the market of solar modules A few years ago there was no special choice of modules from a Ukrainian manufacturer for a buyer.

The use of solar energy is an alternative to non-renewable energy sources. Modern technologies make it possible to use solar panels for street lighting, heating and lighting of small houses. Today, solar panels for summer cottages are no longer uncommon, which allow to provide the economy with electricity in the summer.

Solar panels

A device that is a large number of photovoltaic converters connected into a single system, and there is a solar battery.

For a solar battery, it is important to have direct sunlight, the energy of which is converted into electric current.

Batteries are installed in areas where sunny days are most of the year. True, the geographic latitude also affects the efficiency of solar panels. After all, the farther from the pole, the more powerful the sun's rays. But even in central Russia in winter, solar panels reduce the consumption of electricity from public networks, and in the summer it becomes possible to even sell its surplus.

Solar cells are monocrystalline, polycrystalline and thin-film.

Crystals directed in different directions in polycrystalline batteries reduce dependence on direct sunlight. Such batteries are most common today, they are used to illuminate public buildings and private houses. It is often already found and it is of the polycrystalline type.

Solar panels for summer cottages

Until recently, the main argument against the installation was their cost. Today, domestic industry is starting to produce these products, prices for it are getting lower, the choice is wider, and service is more affordable.

Modern technologies are quite capable of coping with the lighting of the site and ensuring the operation of household appliances. True, this requires a battery and also a charge controller and an inverter that converts direct current into alternating current.

Today you can buy a ready-made set of solar mini-power plants for a summer residence or a small house with an autonomy of work for 24 hours. The power of such a power plant is 235 W with a battery power of 2.4 kW * h.

Solar Batteries

Rechargeable batteries are an important piece of equipment in a modern solar system.

On bright sunny days, solar panels generate significantly more electrical energy than electrical appliances consume, and at night, when lighting is especially important, they do not work at all. This means that it is necessary to accumulate and store electricity for its subsequent use.

Rechargeable and designed for uniform and uninterrupted power supply.

Also, accumulator batteries cover peak loads that are too large for PV modules, use the accumulated energy in the dark, compensate for the difference between the generated and consumed energy in cloudy weather.

Battery connection methods

Most often, one battery is not enough for the full operation of a solar power plant, and you have to use several batteries of the same type. Experts believe that they should generally be from the same batch.

To increase the total capacity of the system, three methods of connecting (switching) the battery are used.

When connected in parallel, the capacities of all batteries are added, and the total voltage is equal to the voltage in one device.

A series connection, on the other hand, allows all voltages to be summed up, and the capacity remains equal to the capacity of one battery in the circuit.

The most productive is the combined series-parallel connection, in which both voltages and capacities are summed.

True, with such a connection, the batteries are subject to imbalance, that is, the total voltage will be constant calculated, but for each individual battery, its readings will change. This phenomenon leads to the fact that some of the batteries are undercharged, and some are charged above normal, and the resource is depleted prematurely.

Therefore, the complete set of each solar system necessarily includes a solar battery charge controller and jumpers, with the help of which the midpoints are connected to self-equalize the voltage in the battery.

Features of batteries for solar systems

A battery pack for a solar cell must meet a variety of requirements. It must withstand a large number of charge / discharge cycles. In this case, self-discharge should be minimal, and the magnitude of the charging current should be large, and the operating temperature range should be wide.

Today, manufacturers are already producing special storage batteries, the so-called solar batteries, which fully meet these requirements.

A set of solar panels with such devices and a charge controller allows you to accumulate energy and store it with maximum efficiency... A grid inverter - convert it to connect household appliances and lighting.

Criterias of choice

You need to choose according to several parameters.

The most important of these is capacity. Based on the required power consumption, the calculated capacity indicator is calculated, increases by 35-50%, and already one or more devices for parallel connection are selected based on it. A battery with sufficient capacity holds energy up to 4 days.

Duration of discharging and charging. Of two devices with the same capacity rating, the one that requires a shorter charging time is preferred.

The capacity of a lead-acid battery depends on the mass of lead in it, therefore, the greater the mass of the battery, the higher its real capacity. When choosing, you need to pay attention to the weight and dimensions of the device.

Manufacturers set for their products a range of operating temperatures and frequency of maintenance, these indicators should also be paid attention to.

The accompanying documents always indicate the period of use of the battery, the number of discharge cycles (the greater this indicator, other things being equal, the better) and the amount of self-discharge per month.

When calculating the parameters of the storage battery, it is necessary to take into account the energy losses during its storage and transformation. The efficiency of modern devices for solar systems is approximately 85%.

Types of solar batteries

Conventional car batteries are not designed for a large number of cycles and are characterized by significant self-discharge. For solar stations, completely different devices are used.

1. AGM-batteries, in the construction of which the electrolyte is in a bound state between the absorbent glass mats. Such a device can be operated in any position; at a low price and a charge depth of about 80%, it can withstand up to 500 cycles and has a high level of charge.

The service life is not so long - 5 years, and the operating temperature range is limited to 15-25 ° C, but they are quickly charged - it takes less than 8 hours for full recovery, can be transported in a charged state and operated in a room with insufficient ventilation.

AGM batteries quickly fail due to overcharging, but they tolerate undercharging quite satisfactorily.

2. The solar gel battery can also work in any position. The jelly-like gel electrolyte is retained in the pores of the silica gel, which acts as a separator for the plates. The indisputable advantage of this design is that the electrodes do not crumble, because all the free space is filled with gel, which means that the possibility of a short circuit is excluded. In addition, they can withstand a full discharge and a significant number of cycles, about one and a half times more than similar AGM batteries. But their price is also noticeably higher.

Despite the price, gel batteries are more economical, do not need maintenance, they can be in a completely discharged state without damage for several days, energy losses in them are insignificant due to low self-discharge.

3. OPzS batteries, the so-called maintenance-free filling devices with liquid electrolyte, are specially designed for low current discharge. They can withstand a very large number of deep cycles, are used, as a rule, in powerful, expensive solar systems, and are quite expensive themselves.

Solar Charge Controller

Electronic devices are designed to monitor and adjust the charge level on the battery. It is they who protect the battery from both complete discharge and overcharge.

Charge controllers are very important elements of solar panels. They provide multi-stage battery charging, automatic shutdown at full battery charge and at minimum charge - loads, connecting PV modules when the battery needs to be charged, and reconnecting loads after charging.

The cheapest and most primitive type of On / Off controllers disconnects the solar panels from the battery when the voltage reaches the limit, preventing the batteries from fully charging and thereby reducing their resource.

PWM controllers operating on PWM (pulse width modulation) are technologies that are economical and effective in areas with high solar activity. They stop charging, allowing the battery to fully charge. Such devices are installed in low-power, up to 2 kW, systems with a low-capacity battery.

MPPT controllers control maximum energy peaks. They are most effective in solar systems, but they are also much more expensive than other models.

Solar Battery Manufacturers

There are not many manufacturers of this type of product on the Russian market.

CSB Battery Co., Ltd (Taiwan) offers lead-acid batteries, manufactured according to a service life of up to 10 years, rated for a voltage of 12 V, with a capacity of 26 to 100 A * h at a price of 2.6 to 8.2 thousand . rubles.

About the same batteries are produced by Shandong Sacred Sun Power Sources Co., Ltd (China).

HAZE Battery Company Ltd (UK) supplies gel batteries with a service life of up to 12 years, an operating voltage of 12 V, a capacity of 15 to 230 A * h and a temperature range of -20 to +50 ° C at prices from 7 to 28 thousand rubles ...

SSKGroup (Russia-Belgium) produces reliable gel batteries for solar panels with a flame arrester with a service life of 15 years, with a capacity of 100 to 180 A * h at prices ranging from 11 to 19 thousand rubles.

Solar cell manufacturers

The main manufacturers of solar panels have long been Japan, Germany, the United States and China. Russian solar panels are assembled from materials produced in these countries. The most popular domestic solar panels with an affordable price are made from polycrystalline silicon produced in Germany and the USA.

Today, Russian manufacturers not only produce solar modules, but also develop new ones, such as, for example, Kvant in Moscow.

The Krasnodar company "Solar Wind" produces not only modules, but also ready-made home solar stations. Designs ready-made solar systems and SolarInnTech from Zelenograd.

There is more and more equipment for solar systems on the domestic market, including ready-made standard projects. But with some engineering skills and perseverance, you can independently calculate the system for specific operating conditions and select the necessary equipment: solar panels, batteries, controllers different manufacturers in a wide price range. In this case, you can save on some components by collecting them yourself from scrap materials, for example, a controller.

Have been field tested on many installations. Practice has shown that the service life exceeds 30 years. Photovoltaic plants operating in Europe and the USA for about 25 years have shown a decrease in the power of modules by about 10%. Thus, we can talk about the real service life of solar monocrystalline modules for 30 years or more. Polycrystalline modules usually work for 20 years or more. Amorphous silicon modules (thin-film or flexible) have a lifespan of 7 (first generation of thin-film technologies) to 20 (second generation of thin-film technologies) years.

Solar modules usually degrade faster in the first 2 years of operation. Thin-film modules lose 10 to 30% of their power in the first 2 years of operation, so usually new ones have a power reserve of about 15-20%. Crystalline silicon modules currently account for about 90% of the PV module market. their degradation is much less and their service life is longer than that of other types of solar modules (see table below).

How quickly do solar panels degrade / lose their efficiency?

Typical power degradation of solar panels is 0.5% per year. As mentioned above, thin film solar panels (a-Si, CdTe and CIGS) degrade faster than mono and polycrystalline panels. Below is a table with data on solar panel degradation produced before 2000 and after 2000. :

What is the expected lifespan of solar panels?

Below is a graph of a typical solar panel power generation warranty from various manufacturers:

As you can see, most of the manufacturers guarantee the operation of solar modules for 25 years, while the power reduction will not exceed 20% by the end of this period.

Many manufacturers give a guarantee for their modules for a period of 10 to 25 years. At the same time, they guarantee that the power of the modules in 10 years will decrease by no more than 10%. Mechanical damage is usually guaranteed for a period of 1 to 5 years.

What will happen to my solar panels after 25 years of use?

We honestly don't know. There is still no sufficient statistical data on this issue, since photovoltaics is a fairly young industry, and the vast majority of modules are currently in operation. made less than 10 years ago. However, the data that exist suggests that solar panels will work much longer than the 25 years promised by manufacturers:

- The 33W solar panel (Arco Solar 16-2000) actually performs better than its specs promised after 30 years of operation.

- The world's first solar panel has been in operation for 60 years.

- Kyocera has reported on solar installations that continue to operate successfully and reliably after 30 years of operation.

The maximum degradation is usually guaranteed by manufacturers to be no more than 20% over 25 years. However, measurements carried out on modules actually working since 1980 show that their production has decreased by no more than 10%. Many of these modules still work with the parameters declared during production (i.e., there is no degradation). Therefore, we can safely say that the modules will work for at least 20 years, and with a high probability they will provide high performance even after 30 years from the date of their start.

Modern solar panel technology has improved dramatically, and the solar panels that are now being marketed are even more reliable, stable and efficient.

All this means that if, when calculating the payback of solar power plants, the service life of solar panels was 20 years, then they will then generate electrical energy free of charge.

We are confident that high-quality solar panels will work and generate electricity in 30-40 years after installation.

What can be done to increase the lifespan of solar panels?

- Avoid physical damage to the panel (i.e. falling trees, branches, being blown off by the wind, scratching the module). The more scratches on the surface of the module, the less its effectiveness. In the worst case, moisture and water can get between the glass and the protective film and lead to short circuit and / or corrosion of solar cell contacts.

- Regular maintenance and cleaning is very important. See Best Way to Clean Solar Panels.

- The more severe the climatic conditions in which solar panels operate, the faster they will degrade. Therefore, in some cases it makes sense to install wind barrier structures.

What is the lifespan of the other components in the solar power system?

Other system components have varying lifespan: batteries have a lifespan of 2 to 15 years (average 4-10 years), and power electronics have a lifespan of 5 to 20 years (average 10-12 years)

Continue reading

How to choose the right solar cells and modules First of all, you need to pay attention to the technical parameters of the solar module. The main ones are listed below. Also, you need to check the workmanship and the absence of visual defects on solar cells, glass, protective film and frame ...

How to choose the right solar cells and modules First of all, you need to pay attention to the technical parameters of the solar module. The main ones are listed below. Also, you need to check the workmanship and the absence of visual defects on solar cells, glass, protective film and frame ...

Solar panels can be bought for power supply of a private house, summer house or other premises. The complexity of their choice lies in the need to create a balanced system of different elements. These include: photo panels and battery, inverter and controller.

How the solar battery works and works

The solar battery is an independent source of electricity. The device consists of a series of semiconductors that convert solar radiation into current. Absorbent panels vary in size from a couple of millimeters to several meters.

The battery consists of two layers with different conductivity. Solar energy knocks out electrons from the cathode and they fall into the wastelands of the anode. It turns out their cycle. Historically, the first solar cell was selenium. But its productivity was low.

In 1954, representatives of the US telecommunications company proposed replacing it with silicon. And after 4 years, a satellite was launched on a photocell from it. The efficiency of monocrystalline material is 17%, and of polycrystalline material - 15%.

Since the production of the first solar panels, their cost has dropped significantly.

For a long service life, the device elements are shunted by diodes. Which reduces the final resistance of the circuit. Usually they are placed on every quarter of the length of the battery. This design is especially important when some of the panels are in the shade. Diodes do not allow them to turn into current consumers.

The accumulated electricity is stored in the battery. The voltage is less than the incoming potential. The charging process and its speed are checked by a special controller.

Lead and gel energy storage devices are considered effective. Their service life is 10-15 years.

The excess current is absorbed by the resistor. Inverters are used to convert direct voltage to alternating voltage.

The performance of a solar cell depends on the angle of its inclination and the cardinal direction in which it is directed. So, the maximum result will be from such a placement of the device:

- south at an angle of 30 ° - 100% efficiency,

- south-east / south-west at an angle of 30 ° - 93%,

- to the east / west at an angle of 93 °.

Benefits and Effectiveness of Standalone Devices

They buy solar panels for summer cottages, private houses, hotels in resort towns. Users note a number of their competitive advantages:

- inexhaustible source of energy,

- general accessibility in any locality,

- environmental Safety,

- noiselessness of the system,

- long service life up to 25 years,

- state support for the development of alternative sources of electricity in European countries,

- the ability to mount additional panels to expand the system,

- low probability of breakage,

- free energy itself,

- system autonomy.

Disadvantages of solar panels for home

The use of solar panels comes with a number of disadvantages:

- high cost of the system,

- the need for a one-time deposit of a large amount,

- low performance compared to traditional power supplies,

- the need for space for placing additional components,

- long payback period,

- the need for constant care,

- battery disposal problems,

- the likelihood of theft of expensive equipment,

- inefficiency in winter, foggy and cloudy seasons.

When solar panels are advisable

The cost of an autonomous power supply depends on its capacity and performance. And the larger it is, the lower the price of units of its constituents.

Powerful solar panels can be purchased from $ 330 to $ 530. In order to provide a house for 4 people with electricity, it will be necessary to invest 15-25 thousand USD.

In Western Europe, the demand for alternative sources of food is higher, because there is a higher wealth of people. In addition, there is the possibility of transferring the accumulated energy to the general network. At the same time, the purchase price from the state is higher than the tariffs for consumption.

It is advisable to use the power of solar panels when there is a lack of electricity in the region. For example, in a resort town, where consumption restrictions are introduced during the “season”.

Or the home is away from the power source. And laying a network of wires is more expensive than the cost of batteries.

It is better to use the energy of the sun when fog and bad weather do not obstruct its flow. For example, in the south of the country on a hill.

For more efficiency of the solar panel, follow the installation instructions that come from the manufacturer.

Autonomous power supply modes

When choosing a solar power supply system, the maximum power required from it must be considered. It is calculated by summing the capacities of all household tools and other electrical consumers. You also need to determine the average daily rate. It depends on the mode of autonomy from the general network.

Complete replacement of the usual power source, accompanied by a disconnection from the city power supply. The required amount of power is determined by the meter readings for previous periods. At the same time, it is advisable to take into account possible future electrical consumers, the reserve for which is better to be done in advance. Usually you need at least 600 kW per month to provide a house for 3-4 people.

With partial power supply, the main power comes from the network, the rest from solar panels. Devices, devices and systems that require more than 2 kW / h or 5 kW / day remain on a traditional power source. For example, underfloor heating, electric boiler, washing machine, heater, iron. This mode will require 2 - 2.5 kW / h.

Moderate electricity supply changes the way you live. Capacious work, like a big wash, is performed periodically 1 - 2 times a month. During the period of high sun activity. Water heating is also limited to hourly supply. The system requires 150 kW per month with a possible average energy consumption of 4 - 6 kW / h. Peak power can reach 10 kW / h.

Basic mode uses 100 kW per month. The owners are in a state of energy saving, constantly monitoring the switching on of the light and other current consumers. Work requiring a lot of power is carried out before lunchtime. So that the battery has accumulated a sufficient amount of charge until the evening.

Emergency mode is used in emergency situations and for several days. After, it is supposed to restore the usual level of power supply from the network. It is used to provide the basic needs of the residents of the house. Average energy consumption per day does not exceed 2 kW with a peak value of 6 kW / h.

After determining the level of required energy, you can proceed with the selection of a specific solar array system.

Choice of solar panels

Solar panels have the following characteristics:

- the size,

- material of manufacture,

- power,

- rated voltage and at peak power,

- current at maximum power,

- short-circuit current

- operating temperature range,

- lifetime.

When choosing photocells, all of the above indicators must be taken into account.

To achieve the required voltage level, the panels are connected in parallel in blocks. It is important to understand that elements of the same type are used to combine. But, if the choice is between a large battery or a pair of small ones, then it is better to give preference to the first option. Since there are no additional connections in it, which increases the reliability of the structure.

Typically, panel sizes are 1 - 2 m² at 220 - 250 watts.

Modern batteries are made from silicon.

How much a solar cell costs depends on its type. Photo panels are mono- and polycrystalline. The first ones are distinguished by greater efficiency at the level of 17.5% with a comparative indicator of 15% of the analogue. But their cost is higher. But in the finished structure, when converting the received energy into costs, the cost of 1 Watt is approximately equal. The service life of the panels is the same. But the activity of the sun is not constant in different periods of the year. Therefore, it is preferable to purchase monocrystalline solar cells.

The rated voltage is the measure for which the device is designed under normal operating conditions. At the same time, the maximum is higher by 5 - 10%.

In the case of solar panels, give preference to 24 volt panels. A higher indicator is rare. And 12V devices are designed for small systems. They are usually used for architectural reasons when space for a battery is limited.

The installation is capable of operating at a certain temperature. The optimal solution is the range from -40 ° C to + 90 ° C.

According to consumer reviews, solar panels function properly for 20 to 25 years. Moreover, their effectiveness decreases by 7 - 8% every 10 years.

Choosing a controller and inverter

The controller is mounted between the solar panel and the battery. It controls the level of voltage coming from the photo panels, depending on the charge level of the energy storage. So at 100% accumulation, overcharging is prevented by disconnecting the voltage supply to the battery.

Expensive technologies track changes in incoming flows and balance them. This is how the maximum possible battery performance is achieved at any time of the day or season. Maximum Power Point Tracking controllers are useful in large systems. And when providing energy to a private house, a rather simplified model. For example, PWM type.

Such devices, with a battery charge level of 80% or more, reduce the voltage of the solar battery and maintain it. In comparison, ON / OFF controllers, which are the cheapest equivalent, simply turn off the system.

It is also important that the control unit can compensate for the temperature and assume the choice of the type of battery.

Manufacturers of solar panels, when abandoning the controller, recommend constantly measuring the battery charge with a voltmeter. And, if necessary, manually turn off the system. Because overcharging decreases the lifespan of the drive.

The inverter converts DC voltage to AC voltage. The input voltage rating should be related to the power of the device. So with its power of 600 W, U = 24 V is sufficient, and, accordingly, 48 V with higher power.

If we talk about the types of inverter, then the least hassle will be a sinusoidal device.

An indirect indicator is the weight of the equipment. Since the transformer is notable for its considerable mass, conventionally, 1 kg of the inverter goes to 100 W. And therefore a high-quality 1000 W converter weighs 8 - 10 kg.

The rated output power must be equal to the power of all electrical consumers.

Battery selection

The battery should be chosen based on the amount of energy that it will store. For this, the daily energy requirement for different consumers is determined. This makes an additional 10% adjustment for conversion losses in the inverter.

If solar panels will be an autonomous power source, then the maximum possible amount of battery charge is important. And in case of backup or emergency mode of the system, it is necessary to give preference to batteries with a long service life.

Starter batteries require constant maintenance and are used with low system power. Gel counterparts are less demanding to maintain and can store more energy. Sealed and flooded batteries provide long runtime at high power levels. AGMs are primarily used for standby power saving mode.

With the same characteristics, the heavier counterpart will have the best real performance.

Solar battery maintenance

Solar panels require more maintenance than a fixed grid. Their surface must be systematically cleaned of dirt. Such as bird droppings, dust, traces of precipitation. Since dirty panels absorb less solar energy.

For cleaning, it is enough to wash them with a stream of water from a hose. And to remove snow, use a stick like an old mop with a rubber layer.

It is also necessary to cut off tree branches that cast shadows on the surface of the batteries. Ideally, it is better that there are no tall plantings at all in the adjacent territory of the house.

Check the condition of the system mounts twice a year. Change them if necessary.

Before installing an autonomous power supply, two questions usually arise: "How long will the system last?" and "How long will it pay off?" After all, it is on the answers to these questions that the expediency of the costs of purchasing and installing an autonomous circuit depends. The lifespan of solar panels varies. It depends primarily on the type of panels themselves.

Terms of service

As practical tests have shown, the service life of solar panels is at least 20 years. After a certain amount of time (15-20 years, depending on the type and characteristics of the photocells), a slight decrease in power is observed, which continues in the future. As a rule, batteries based on single crystals work up to 30 years, on polycrystals - 20-25 years. Thin film batteries of the latest generation also last about 20 years.

The standard warranty for most solar panel manufacturers varies quite widely - from 10 to 25 years. Such a spread is associated with the characteristics of the photocells themselves, their type (poly-, mono-), class (“A”, “B”, “C”), the quality of the protective front cover, etc.

Manufacturers guarantee that during this period the capacity of their products will decrease by no more than 10%. A drop in power by a more significant amount is fraught with a critical decrease in the production of the entire system, since every watt of energy produced is very important for solar power plants. Amorphous silicon batteries usually lose 10-40% of their capacity in the first seasons, after which their production "freezes" at this level.

What affects the service life

The standard design life for crystalline solar panels is 30 years. To find out the rate of real aging of elements, a whole series of different kinds of tests are carried out. They show that the photocells themselves have a very long service life, their degradation after several decades of use is minimal.

The drop in the performance of solar panels is associated with three factors:

- destruction of the film sealing the module;

- clouding of the film layer between the photocells and the protective glass;

- destruction of the back film of the solar battery.

To seal solar panels (as well as as a film layer), EVA (ethylene vinyl acetate, the so-called "ethylene vinyl acetate") film is used. The back side of the panel is usually a polyvinyl phosphate film.

Such film protection is necessary to protect the photocells and soldered joints of the panel from moisture. Under the influence of UV rays of the solar spectrum, the films are gradually destroyed, they lose their elasticity and are easier to mechanical stress. As a result, the tightness deteriorates and moisture begins to seep into the interior of the panel more actively.

In addition, the EVA film between the glass and the photocells also loses its optical transparency, which leads to a decrease in the absorption of sunlight. And due to microdroplets of moisture, the soldered joints gradually begin to corrode, which leads to an increase in contact resistance, its overheating and subsequent destruction.

As a rule, manufacturers guarantee no more than 20% degradation in the performance of their solar panels over 25 years. However, this applies only to reputable companies that carefully monitor the quality of products. Less conscientious companies when assembling panels save on everything in order to set the final price of the product as low as possible.

Such savings leads to the fact that poor-quality (or unsuitable for specific conditions of solar panels) materials are used for sealing. As a result, the destruction of contacts can be observed as early as the next season, which leads to a sharp drop in power (up to 30-40%). Especially often this phenomenon can be observed on cheap garden lamps with photo batteries.

Additional factors

The service life is also influenced by the quality of the EVA film itself, as well as the protective laminating coating. A poor-quality coating gives a noticeable shrinkage already in the very first season. This leads to an almost complete depressurization of the panel, a sharp decrease in efficiency and failure of the product.

Another aspect is the thickness of the connecting conductors and busbars. It must be sufficient to pass currents of exactly the power that is stated in the solar panel's passport. Moreover, the busbar thickness should be greater than that of the conductors connecting the photocells. If the tire is too thin (which is often found in cheap panels of little-known companies), then it will soon fail.

It also affects the life and quality of the soldered joints. A poorly executed soldering will break down very quickly and without corrosion, as these contacts themselves overheat. Therefore, the reliability of the soldered joints is an indispensable condition for long-term performance.

Payback period

The payback period for solar panels depends on several factors:

- Equipment type (poly or monocells, single or multi-layer solar cell structure). The initial costs depend on this, since the cost of solar panels different types varies quite a bit.

- The number of panels to be installed. That is why it is very important to carry out an accurate calculation of the entire system in advance.

- Geographic latitude, more precisely, the magnitude of insolation: the more sun hits the working surface of the module, the more it generates energy and the faster it “beats off” the costs.

- Energy prices in the region. The cost of a kilowatt-hour of electricity will determine the difference in the cost of the energy generated by the sun and the energy received from the central power grid. In other words, how much more profitable it is to generate "solar electricity".

On average, for a private house, the payback period is 2.5-3.5 years in Central European countries and 1.5-2 years in southern European countries. For Russia, this indicator varies in the average range from 2 to 5 years. However, it must be remembered that with the improvement of manufacturing technologies, the efficiency (energy production) of the panels increases, which means that the payback period is gradually decreasing.