Closing the armature winding to the body

This kind of short circuit occurs due to mechanical damage to the insulation. The reasons for mechanical damage are: the presence of protruding sheets of active steel and burrs in the grooves, tight filling of the groove, loose laying of the winding in the grooves, which causes the wires to move in the groove under the action of centrifugal forces during rotation, loosening of the bands, etc.

In addition to mechanical damage to the insulation, the reasons for a short circuit to the case can be insulation moistening, solder getting into the grooves and frontal parts, strong and prolonged overheating of the machine, unsoldering of connections, and more.

The short circuit of the armature winding to the body can be detected by a control lamp (Figure 1, a). When checking, the lamp is connected with one end to the network, and the other to the collector. The second (free) end of the net is attached to the armature shaft. If the light comes on, it indicates that the winding is shorted to the body. You can also use a megohmmeter for this check.

Figure 1. Checking the short circuit of the windings on the case.

a- a control lamp; b- megohmmeter: 1

- megohmmeter; 2

- collector; 3

- shaft; 4

- stand

The location of the winding closure to the case can be determined according to the diagram shown in Figure 2.

|

|

| Figure 2. Determination of the location of the winding closure to the case. a- voltage drop; b- readings of the device when finding closures (for loop winding); v- listening |  |

In the diagram shown in Figure 2, a, DC power supply is connected to the brushes through a fuse NS... The current is regulated by a rheostat R... Probe of one of the wires from the millivoltmeter mV attached to the core or shaft of the armature, and the others touch any plate of the collector. The source of current can be a rechargeable battery or a direct current network with a voltage of 220 or 110 V. When finding a fault, a current of 6 - 8 A is sufficient. A millivoltmeter is taken with a scale of up to 50 mV.

With looped winding, the connection to the collector is made at two diametrically opposite points. With a wave winding, the connection to the plates is made at a distance of half a step along the collector.

When closing to the body in the looped winding, the arrow of the device will show a deviation equal to the sum of the voltage drops in the sections that are between the section closed to the body and the one to which the probe is connected (Figure 2, b, position I- solid arrow). The probe attached to the manifold is moved to one side and the other. When it approaches the section closed to the body, the instrument readings will decrease (position II- dashed arrow), since the number of sections on which the voltage drop is measured will decrease. When the probe is connected to the section that is shorted to the body, the millivoltmeter needle will go to zero (position III). If you move the probe further, then the arrow of the device will deviate in the opposite direction (position IV).

When checking the wave winding, the lowest readings will be given by the collector plates, either directly shorted to the housing, or shorted to the housing through the winding sections.

The short circuit is also determined by "listening" to the winding (Figure 2, v). For this battery and buzzer 3 attached to the armature shaft and any collector plate. One terminal of the telephone is also attached to the shaft. 1 ; another pin it is moved over the collector 2 ... The closer the conductor is moved to the closed plate or section, the weaker the noise in the telephone. When the conductor touches the section closed to the body, the noise disappears.

If the above methods do not give positive results, then you have to divide the winding into parts by desoldering and check each part separately with a megohmmeter. If a short circuit is detected in one of the parts of the winding, it continues to be divided into parts until a section closed to the case is found.

Short-circuits to the case are eliminated as follows:

- if the short circuit occurs at the points where the sections exit from the grooves, then small wedges made of fiber, beech or other insulating material are driven under the section;

- if the short circuit occurs in the groove part of the section, then the section will be re-insulated or replaced with a new one;

- when the winding becomes damp, they listen to it;

- if a closure of the plates to the case is detected, then the collector should be repaired with disassembly.

Turn-to-turn closures

This type of short circuit is the connection of turns inside the winding due to damage to the insulation of the winding wires. Most often, turn-to-turn closures occur when the insulation of the conductors is damaged during straightening and settling of the coils, when laying the winding, due to the ingress of solder or chips between the turns, when the winding breaks down on the body, due to the crossing of wires in the slotted part with a loose winding, and the like.

Turn-to-turn closures can be in one or more sections of the armature or between sections due to the closure of adjacent collector plates. When closed between the ends of the section or between the collector plates, as well as when individual turns of the section are connected to each other, closed loops are formed in the armature winding.

In a looped winding, a short circuit between two adjacent plates causes only the section that is connected to these plates to close, and the number of turns acting in the winding is reduced by the number of turns contained in one section.

In a wave winding, a closure between two adjacent plates causes a series of sections to close, which are enclosed in one complete loop around the armature. Their number is equal to the number of pairs of poles of the machine.

In short-circuited circuits, when they rotate in a magnetic field, an electromotive force (EMF) is induced, which causes large short-circuit currents due to the low resistance of these circuits. The short-circuited turns that appear during the operation of the machine are very hot by the current passing through the winding and usually burn out.

How to determine the turn-to-turn circuit of an electric motor? In armatures with a wave winding, as well as in windings that have equalizing connections with a significant number of closed sections, it is impossible to determine a short-circuited branch by heating, since the entire armature heats up. Sometimes the place of turn short circuits can be detected during an external examination by the charred and burnt insulation of the section.

The simplest and most common cases (for example, short circuits of the turns of one section, between adjacent collector plates or between adjacent sections located in the same layer of the winding) are detected by voltage drop, listening and other methods.

Method for determining damage by voltage drop

|

| Figure 3. Checking the absence of a short circuit between the turns of the armature by voltage drop |

This method (Figure 3) is as follows. To a pair of manifold plates 1 direct current is supplied by means of probes 3 ... Probes 2 measure the voltage drop across the same pair of plates. When closing in a section that is connected to the tested pair of plates, a lower voltage drop is obtained at the same current than on the other pair of plates, between which there is no short circuit. The more short-circuited turns, the lower the voltage drop. The smallest voltage drop (or equal to zero) will be at a short circuit between the collector plates themselves.

This checks the entire armature and compares the measurement results. The armature should be checked with the brushes raised. The circuit parameters are the same as in Figure 2, a.

To prevent damage to the millivoltmeter (Figure 3), you must first apply the probes to the manifold 3 and then the probes 2 ; take away the probes in the reverse order.

This method gives good results when detecting short circuits between turns in a section with a small number of turns (bar windings). In multi-turn sections, when one or two turns are closed, the difference in millivoltmeter readings on the collector plates of a serviceable section and a damaged one may turn out to be insignificant.

Figure 4 shows circuits for detecting turn-to-turn faults using a telephone and a steel plate. The test setup consists of an electromagnet 1 powered by alternating current of increased frequency. Anchor 3 installed above the electromagnet. With a turn-to-turn closure in any section, a large current will flow in it, which will be detected by heating. By phone 2 and electromagnet 4 you can quickly identify a groove with a damaged section. With working sections of the winding in the phone 2 a faint sound of equal strength is heard. If one of the sections has a turn-to-turn circuit, then the sound in the phone is noticeably amplified.

Figure 4. Checking the armature for turn-to-turn closure.

a- by phone; b- using a steel plate

For a complete check of the winding, you need to rearrange the electromagnet 4 along the teeth of the anchor until the latter is bypassed. If a thin steel plate is brought up to the teeth of the core covering the defective section 5 (Figure 4, b), it will start to rattle. In this way, the closure of adjacent collector plates is detected, which causes the same phenomena as the turn-to-turn closure.

To determine turn-to-turn closures, the circuit shown in Figure 2 can be used, v... For this, the second conductor is not connected to the shaft, as shown in the figure, but to the collector plate. Phone wires 1 attached to two adjacent plates.

A section with a turn closure is usually replaced with a new one. Re-insulating only one point of short circuit can be limited only in case of incomplete contact at the point of short circuit, and even then in the absence of other damage to the insulation.

If necessary (as a temporary measure), with a small number of collector plates, the damaged sections are shut down from operation. Switching off one section does not noticeably affect the commutation of the machine.

Breaks in the armature winding

Breaks in the winding occur due to the melting of the solder due to overheating of the windings during overloads, short circuits, breaks from frequent bending of the winding frontal parts, and the like. Breaks most often occur in thin wire windings due to its low mechanical strength. A broken winding or poor contact greatly impairs the commutation of the machine and can cause significant sparking on the collector and its burning. If the armature works for a long time with a break, then the arc formed at the break point can gradually burn through the insulation and lead to a short circuit of the winding on the body.

In a looped winding, a break is accompanied by sparking on the collector and burning of two adjacent plates to which the damaged section is attached. With a wave winding, several pairs of adjacent plates (according to the number of poles) burn out, to which sections of one series circuit of this winding are connected. In this case, the edges of the adjacent plates facing each other are burnt.

Both with poor contact and with a break in the presence of equalizing connections, they can burn, except for the plates related to the faulty sections, and the collector plates spaced from them by double pole division and associated with equalizing connections. The break point can be determined by the voltage drop.

If any section breaks (Figure 5, a) there will be no current in the entire half of the winding in which the faulty section is located, therefore the device will everywhere show zero (positions II and III), unless the instrument wires are connected to the ends of the broken section. In this case, the circuit will be closed through the device and its arrow will deviate in the same way as if the wires of the device were connected directly to the current source (position I).

Figure 5. Finding one ( a) and two ( b) breaks in the loop winding

With two breaks (Figure 5, b), if the collector plates are closed in pairs, the device will not show anything in the entire area between the plates to which the voltage is applied. To find the points of breaks, proceed as follows: one of the probes from the wires connected to the device is installed on the collector plate, to which power is supplied, and the other is moved along the collector, starting from the other probe supplying power. In this case, the readings of the device will be maximum (position IV). When the probe moved along the collector "passes" the break point, the device will show zero (position V). Having found one cliff, they look for another in the same way.

In case of breaks in the wave winding, the greatest deviation will take place on several pairs of plates located in pairs at a distance of a step along the collector from each other. Breaks in an armature having parallel branches can also be determined by measuring their resistance. When one of the sections breaks, the winding resistance increases sharply.

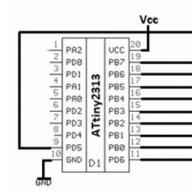

After laying the armature winding in the grooves of the core, it must be checked for correct connection with the collector plates. This check is carried out after the ends of the winding sections have been cleaned to a metallic sheen and embedded in the slots of the collector plates. Figure 6 shows a diagram of the installation required for this purpose. On wooden racks screwed to a wooden base 3 , the anchor is being set 2 ... An electromagnet is placed under the anchor 5 , the core of which is made of U-shaped sheets of electrical steel. Electromagnet winding 8 consists of two coils, which are connected so that when current passes through them, two opposite magnetic poles appear WITH and NS... The coils are powered by a rectifier 4 through rheostat 7 ... The switch is a foot pedal 1 ... Fork 9 millivoltmeter 6 connects to two adjacent plates. At the moment of opening the contacts with the pedal 1 pulses are induced in the armature winding. With the correct connection of the winding and the position of the plug 9 on any adjacent collector plates millivoltmeter needle 6 should deviate in the same direction and approximately to the same scale division.

Pole winding faults and their elimination

Pole coils are less prone to damage as they are fixed to the poles. Most often, the coils are damaged at the corners inside the coil, at the exit point of the inner lead-out end due to improper installation of it at the beginning of winding, and the like. The causes of damage include a violation of insulation due to the fact that it is poorly tensioned, uneven laying of insulation, protrusions and burrs of the metal frame, and more. The most common faults of the pole windings are: open or poor contact, turn-to-turn short-circuits and short-circuit of the windings to the case.

Turn-to-turn closure in pole coils

A damaged coil with a significant number of closed turns has reduced resistance. It can be easily detected by measuring the resistances of all coils with a measuring bridge, a tester, ammeter and voltmeter (direct current) and others. When measuring resistance by the ammeter and voltmeter method, the test coil is connected to the network through a resistance, which can regulate the current in the coil. According to the readings of the ammeter and voltmeter, the coil resistance is found according to Ohm's law. The resistance of all coils without turn closures is the same. Coils with closed turns will have less resistance than coils without closed turns.

Short-circuits in the pole windings, if they are not at the output ends, are eliminated by partial or complete rewinding. The coils are unwound from the coil and at the same time they are inspected. If the turn short circuits are caused by moisture in the insulation, then the coil should be dried.

Interruptions in the pole windings

Breaks in the pole windings occur only in coils that are made of wire of a small cross-section. The break point can be determined with a voltmeter, which measures the voltage on all coils (Figure 7, a). In the event of a break in the coil, a voltmeter connected to the terminals of the damaged coil will show the full voltage of the network. On serviceable coils, the voltmeter will not give deviations. A break can also be detected with a test lamp or megger. Breakage, as well as poor contact in accessible places, are eliminated by soldering.

Figure 7. Determination of the cliff location ( a) and closure to the case ( b) in the pole windings

Closing the winding of the poles to the case

The short circuit of the winding of the poles to the case can be determined if a direct current is passed through the entire winding. One end of the voltmeter (Figure 7, b) is connected to the body of the machine, and the other (free) is connected to the output of the coil. The voltmeter will show the lowest voltage at the terminals of the coil closed to the case.

The test of the serial winding or the winding of the additional poles is carried out at a reduced voltage, the value of which is regulated by a rheostat connected in series. Instead of a voltmeter, a millivoltmeter is used to measure voltage.

A coil closed to the body can be detected with a test lamp or a megohmmeter. For this, the coils are disconnected and checked separately. To eliminate the short circuit to the body, remove the coil from the pole core and inspect the points of contact with both the body and the bed. Short-circuits to the case are eliminated by re-insulating the coils, installing insulating gaskets, drying with moistening and other methods.

The correct connection of the pole coils is checked with a compass or a magnetized needle (Figure 8). To do this, a direct current is passed through the pole windings and a compass or arrow is brought to each coil. If the alternation of the polarity of the poles is correct, then when moving, for example, the compass inside the car (with the anchor removed) from pole to pole, the compass needle will alternately be attracted to the poles by one or the other end.

If, touching the refrigerator, you feel light and unpleasant tingling, then current is leaking to its body. And this is a direct threat to your health and even life!

The lower limit of sensitivity for dry skin of a human hand is 30-40V. The permissible norm for health is 36V.

On the body of the refrigerator, there may be up to 110V alternating current! This is almost half of the mains voltage (220V).

Hence the simple conclusion: if your refrigerator began to "fight", immediately call the master VseRemont24 to your house.

Note! The problem of current leakage to the refrigerator body may not be hidden in the refrigerator itself, in outlet to which it is connected!

Modern refrigerators are quite powerful equipment that draws a lot of electricity. The refrigerator must be connected to earthed socket!

If your house does not have three-phase wiring with “ground” (and the probability of this is very high!), It makes sense to do this, and also reinstall the correct outlet.

If you have a grounding in the outlet, check if the contacts are not oxidized, this can lead to the fact that grounding does not occur.

Note that most refrigerator manufacturers, when creating their "smart" units, expect that they will be connected to grounded sockets!

A refrigerator, on the body of which a current flows, categorically use forbidden! Remember that such a refrigerator should never be touched with wet hands, especially when the motor is running. Also, do not touch the refrigerator and heating battery at the same time.

The situation is especially dangerous when the refrigerator is installed on a metal stand.

After the first time, when you feel a slight electric shock, unplug the refrigerator and call the VseRemont24 master! It is especially important to do this if there are children and animals in the house.

The VseRemont24 master will arrive at the most convenient time for you with a special diagnostic device - a megohmmeter. This device allows you to find out exactly where the insulation of the wiring is broken, because it is wiring problem- the most common reason that the refrigerator is short.

The VseRemont24 master will arrive at the most convenient time for you with a special diagnostic device - a megohmmeter. This device allows you to find out exactly where the insulation of the wiring is broken, because it is wiring problem- the most common reason that the refrigerator is short.

The following may be faulty in the refrigerator:

- fork,

- electrical wire,

- a wire connected directly to the motor-compressor,

- thermostat knob.

Any of these parts master VseRemont24 quickly and efficiently will replace to a new, “native” one for the brand and model of your refrigerator.

Repairing an electric refrigerator, as a rule, does not take much time, the malfunction will be eliminated within an hour!

The master will announce the exact price to you after diagnostics and finding out the reasons for the breakdown. In addition, the repair price always depends on the brand and model of the refrigerator.

Do not doubt that after the repair carried out by a highly qualified master VseRemont24, you will be safe again, and the refrigerator will be with properly working household appliances.

What is protective earth? What is the scope of its application?

Protective grounding is a deliberate electrical connection to earth or its equivalent of non-conductive metal parts of electrical installations that may be energized.

The area of application of protective grounding is three-phase networks with voltage up to 1000 V with isolated neutral and above 1000 V with any neutral mode.

What is a short circuit to the body of an electrical installation? What is the main reason for a short to frame? A short circuit to the case is an accidental electrical connection of a current-carrying part with metal non-current-carrying parts of an electrical installation.

In what case and how dangerous can it become dangerous for a person to touch the body of an electrical installation isolated from the ground?

If the electrical installation is isolated from the ground, then in the event of a phase short circuit to the case, touching the installation will be as dangerous as touching the phase conductor. - 220 V. In this case, a life-threatening current will pass through the human body

I h = UNS/Rh =Uf /Rh = 220/1000 = 0.22 A = 220 mA

where Upr - contact voltage, V; Uph - phase voltage, V; R is the resistance of the human body, in the calculations taken as 1000 ohms.

What is the operating principle of protective grounding?

Operating principle protective grounding of electrical equipment is to reduce the touch voltage to safe values UNS, due to a short circuit to the case. This is achieved by reducing the potential of the grounded equipment ph 3 (reducing the resistance of the protective grounding R 3 ),

How can the potential be reduced when shorting to the caseal earthed equipment?

Reducing the resistance of the protective earth R 3

When a phase is closed to the body of a grounded installation, what determinesthe magnitude of the touch voltage?

Then, in the event of a phase closure to the body of a grounded electrical installation, the contact voltage Upr under which the person who touches the body will be-

UNS= f 3 - phos

where f 3 is the potential of the body of a grounded electrical installation, V; phos - the potential of the foundation (site) in the place where the person stands, V.

Will the safety increase when the resistance of the protectivegrounding?

No, because the principle of protective grounding is achieved by reducing the potential of grounded equipment ph 3 (reducing the resistance of protective grounding R 3 ), as well as by increasing the potential of the Foss foundation in the place where the person stands, to a value close to the potential of the grounded equipment.

At what minimum value of the AC voltage in all cases should the protective grounding be carried out?

According to the Rules for Electrical Installations, protective grounding should be performed: at a voltage of 380 V and above alternating current in all cases;

What is a grounding device? What distinguishtypes of grounding devices?

A grounding device is a set of grounding conductors - metal conductors - electrodes 7 in direct contact with the ground, interconnected by a strip 6, and grounding conductors 3 connecting the grounded parts of the electrical installation 1 to the grounding electrode.

Depending on the location of the ground electrode relative to the electrical equipment to be grounded, two types of grounding devices are distinguished: remote and contour.

What is a group ground electrode system? What are its advantagesbefore a single?

V loop grounding device(see Fig. 2) a group of earthing switches is used, consisting of several parallel-connected single earthing switches (electrodes) 7, which provides the lowest resistance of the protective grounding.

With a group earthing switch in the current spreading zone, an increase and equalization of potentials on the surface of the site is observed. As a result, the contact voltage is reduced and, consequently, the safety of people working on the protected site is increased.

What are the advantages of a loop grounding device? At what distance from each other should the electrodes be placed in it?

In the event of a short circuit to the electrical installation case, current flow into the ground from all the electrodes of the ground electrode system occurs simultaneously (see Fig. 2). On the graph of the distribution of potentials on the surface of the protected site, obtained by adding potential curves from each electrode separately, it can be seen that with a group ground electrode in the current spreading zone, an increase and equalization of potentials on the surface of the site is observed. As a result, the contact voltage is reduced and, consequently, the safety of people working on the protected site is increased.

When placing the electrodes at a distance of no more than 8 - 10 m from each other, the maximum values of the touch voltage in this case will not exceed the permissible levels.

What is allowed to be used in enterprises as a naturalearthing switches?

As natural earthing you can use: various metal structures of buildings that are connected to the ground; reinforcement of reinforced concrete structures; lead sheaths of cables laid in the ground, water pipes and other metal pipes, with the exception of pipelines for flammable liquids, combustible or explosive gases, as well as pipelines covered with insulation to protect against corrosion.

What are used as electrodes of artificial grounding conductors?

For artificial earthing usually vertical and horizontal electrodes are used. Steel pipes, steel corners, metal rods, steel rods, etc. are used as vertical electrodes. Strip steel or round steel rods are used to connect vertical electrodes.

What value should be the resistance of protective groundinginstallations with voltage up to 1000 V? How often should it be monitored?

When current flows from the case to the ground 1 3 (see Fig. 1) through a low resistance of protective grounding Rz, which in electrical installations with voltages up to 1000 V should not exceed 4 ohms.

The value of which parameter of protective grounding depends on the effectthe vigor of his action? How often should this parameter be monitored?

From the value of the resistance of the protective grounding Rz.

In accordance with the requirements of the Rules for the Installation of Electrical Installations, the resistance of the protective grounding is monitored before putting the grounding into operation and periodically, but at least once a year.

How touch voltage will change with increasing distancebetween a person and a ground electrode?

The tension rises. Then, in the event of a phase closure to the body of a grounded electrical installation, the contact voltage Tsch, under which the person who touches the body will be

and SCH = f 3 - phos,

where f 3 is the potential of the body of a grounded electrical installation, V; phos - the potential of the foundation (site) in the place where the person stands, V.

What is zeroing? VToWhat electrical networks does it apply to?

Zeroing is a deliberate electrical connection with the neutral protective conductor of the housing and other metal non-conductive parts of the electrical installation that may be energized.

Grounding is used in networks with a solidly grounded neutral.

What is called a zero protective conductor? Than a zero prowater differs from the zero protective conductor?

Zero protective conductor PE is called a conductor that connects neutralized parts, for example, the body of an electrical installation with a dead-earthed-gene neutral of the network.

Zero protective conductor must be distinguished from neutral wire N, which is also connected to a solidly grounded neutral, but is designed to supply current to electrical equipment.

What is the purpose of the neutral protective conductor?

Appointment zero protective conductor - creating an electrical circuit with low resistance so that the short-circuit current Isc is large enough for the protection to quickly operate.

When does grounding eliminate the risk of electric shock?

Zeroing is used to eliminate the danger of electric shock in case of touching metal non-current-carrying parts of electrical installations that are energized due to a short circuit to the case.

What is a short circuit to the body of an electrical installation? What is the mainthe reason for the short circuit to the case?

Closure to the case- accidental electrical connection of the current-carrying part with metal non-current-carrying parts of the electrical installation.

The main cause of a short circuit to the case is damage to the electrical insulation of live parts that are energized.

In the case of a short circuit to the case and the absence of zeroing under whatthe tension can be a person touching the body?

If the electrical installation is isolated from the ground, then in the event of a phase closure to the case, touching the electrical installation will be just as dangerous as the phase wire - a person may be energized by touching Upr practically equal to the phase voltage of the network - 220 V.

What is the principle of grounding? Which of the devices is the maximumcurrent overcurrent protection provides more safety?

Operating principle grounding - transformation of the short circuit to the case into a single-phase short circuit between the phase and the neutral protective conductor, as a result of which the maximum current protection is triggered - fuses or circuit breakers, and an automatic disconnection of the damaged installation from the mains is provided.

When protected by circuit breakers, greater safety is ensured.

What devices are used as overcurrent protection? What is the response time for each device?

The shutdown speed of the electrical installation from the moment the voltage appears on the case is 5 - 7 s when the electrical installation is protected by fuses and 1 - 2 s when protected by circuit breakers.

What parameter of the neutral protective conductor determines the effectthe activity of the zeroing action?

What will be the current path in the event of a short circuit to the body of a grounded electrical installation?

What factor determines the speed of protection response? What value should this factor be according to the requirements of the PUE?

According to the instructions of the Electrical Installation Rules (PUE), the short-circuit current must be at least 3 times the rated current of the fuse-link of the fuse or the trip unit of the circuit breaker.

Taking into account the results of the research, name the factorson which the effectiveness of the grounding action depends.

From the short-circuit current, which must be at least 3 times the rated current of the fuse-link of the fuse or the trip unit of the circuit breaker.

For what purpose should the neutral protective conductor have a repeatedgrounding?

To reduce the risk of electric shock arising in the event of a break in the neutral protective conductor PE and the phase is short-circuited to the installation body behind the break point (Fig. 4), the neutral protective conductor must be re-grounded.

How does it reduce the risk of electric shock in the event of a break in a neutral protective conductor, which is re-grounded?

.

In the event of a break in the neutral protective conductor, which has a repetitiongood grounding, in case of a ground fault, what will be the current path? Why notdoes the overcurrent protection work?

If, however, the neutral protective conductor is re-grounded, then when it is broken, the current circuit through the ground will remain, as a result of which the voltage of the neutralized enclosures of electrical installations located behind the break point will decrease to approximately 0.5 U . Consequently, re-grounding significantly reduces the risk of electric shock when the protective conductor is missing, but cannot eliminate it completely.

Why is it forbidden to install in the neutral protective conductorfuses, switches, switches?

It is forbidden to install fuses, circuit breakers and other devices in the zero protective conductor that may violate its integrity.

3923 0 0

100% way out of the situation when there is no protective grounding

October 20, 2016

Specialization: master for interior and exterior decoration (plaster, putty, tile, drywall, wall paneling, laminate and so on). In addition, plumbing, heating, electrical, conventional cladding and balcony extensions. That is, repairs in an apartment or house were done on a turnkey basis with all the necessary types of work.

Currently, about 95% of household appliances are manufactured with the need for grounding. This is especially true for those units that are associated with water:

- dishwashers;

- pumps;

- electric water heaters;

- washing machines, etc.

When such a device works without protective grounding, it can shock, which was more than felt by housewives who have automatic machines.

Grounding if not present

Note. There are four types of grounding: protective, operational, grounding and grounding.

What is protective earth and ground fault

We will not go into the terminology, but we will find out at the core what is needed for everyday life. Let's start with the definition - grounding is the deliberate connection of a grounding device to a specific point in electrical equipment or a network.

- of all four types of grounding, we are only interested in two - protective and short-circuit to the case;

- the essence of protective grounding is to drain the current to the ground, if a phase current enters the ground, which triggers the RCD;

- in new houses, a working grounding is provided, that is, on the electrical panel there is a special bus, where the third conductor is connected;

- but in old houses built by Stalin, Khrushchev and Brezhnev, this function is not provided;

- here everything is explained quite simply - during their construction, there was simply no need for grounding;

- in old houses there is no way to make protective grounding, so here you can make a short to ground, the diagram of which you see above;

- the essence of such a connection is as follows - zero is shunted with mass and if the phase current enters the case, then a short one occurs, from which the residual current device (RCD) immediately triggers - it must be installed!

The residual current device for household appliances, if it is connected to only one of them, should not be more than 16A. Otherwise, there may be a delay with the disconnection.

Yourself with a mustache

In front of you is an electrical panel, which is located at each entrance area. It powers everything located on that floor - there can be two, three, four or even five (depending on the type of building).

On the right side of the photo, you see the bus to which the wires are connected - this is zero. But if the shield had a ground, then there would be another bus of the same kind, to which you would connect the third ground wire.

Sometimes a short to ground is made right here, on the shield - that is, a wire is pulled from the electric boiler from the ground terminal (or from the casing) and connected to the zero bus. Personally, I do not see the point in this - why go so far if everything can be done on the spot.

In the picture above, you see the panel of the GORENIE boiler, where on the left there are pads for connecting wires - phase, zero and earth, which are located from left to right. There is also a shunt jumper that connects zero to ground.

Agree, this is much more convenient than dragging a separate wire to the switchboard at the entrance, and connecting it to zero there. It is noteworthy that such a small jumper performs the same function as a long wire, so I advise you to do this.

Those residents who have old-style electric boilers that do not have a ground terminal can also make the same connection. After all, as you understood, the point is to short circuit to the case, therefore, bypass zero directly with the casing. Do not forget that the boiler should be connected through an RCD.

A short to ground can be made through an outlet by short-circuiting the neutral and ground terminals, as shown in the photo. In this case, it is better to pass the wire from the back (it is not difficult to pull the socket out of the socket box), but here I left it in front for clarity.

To take action, turn off all electrical appliances in the apartment and find the zero terminal on the outlet with the indicator. If the devices are not turned off, then zero will glow, like the phase, and it will be difficult for you to determine it.

Then, with a piece of wire with a cross section of at least 0.5 mm2, install a jumper between zero and ground - absolutely all devices can be connected here.

In fact, this way you can save yourself and your family not only from unpleasant sensations, but also, in some cases, save life and health, since everyone's perception of electric shock can be different.

These are far from empty words, and in any RES or PES you can be provided with many fatal cases from an electric shock, and at low voltages.

Conclusion

For those who have doubts, I propose to conduct such a test at home - take a battery-powered indicator and check the machine during operation - in 90% of cases it will light up! For sensitive people, this is expressed in the pinching of an electric shock.

The option I proposed removes this problem completely and 100%. If you have any suggestions, notes or questions - join my blog on this page.

And for a more detailed acquaintance, I made a video especially for you - look!

October 20, 2016If you want to express gratitude, add clarification or objection, ask the author something - add a comment or say thank you!