- 5 programmable digital inputs

- Logic PNP / NPN

- Pulse input 20 - 5000 Hz

- 1 analog input 0-10 V or 0-20 mA

- 1 analog input 0 - 20 mA

- Thermistor input (analog or digital)

- 1 analog output

- 1 relay, ~ 240 V, 2 A

- RS 485

- Modbus RTU

Built-in RFI filter for Danfoss inverters

Radio frequency interference from the motor cable is limited by the built-in RFI filter, which ensures operation with cables up to 15 m (shielded) and 50 m (unshielded) in accordance with European standards.

Small housing size for panel mounting Danfoss VLT AQUA Drive FC 202 series

The IP20 version contains two independent fans for maximum reliability. Only a small fraction of the air passes through the electronic components, which increases the service life. A hinged aluminum door provides easy access to auxiliary input and output options and control circuits. The IP21 / Type 1 actuator can be supplied as a complete solution or as a stand-alone device with easy access to the control terminals via a removable snap-on top panel.

Robust housing for heavy duty Danfoss frequency converters VLT AQUA Drive FC 202 series

Danfoss IP55 / NEMA 12 or IP66 actuator enclosures are designed to operate in harsh environments containing gas, dirt and dust. The electronic part is completely isolated from the cooling air in order to increase its service life. All EMC terminals and connections are located inside the drive enclosure under a sturdy front panel for maximum protection. When ordering an IP66 enclosure, the heatsink is supplied with a corrosion-resistant coating (IP66 enclosure versions are available up to 90 kW)

With automatic PI control, the drive checks the system's response to self-corrections - and modifies its own parameters so that accurate and stable operation is achieved fairly quickly. The PI gains are continuously changed to compensate for the load characteristic.

Possible in pressure feedback mode. Prevents water hammer, ruptures of water lines or breakdown of spray heads.

Possible in pressure feedback mode. Prevents water hammer, ruptures of water lines or breakdown of spray heads.

This property of the actuator allows the detection of a water leak or a ruptured line. When the end of the characteristic is reached, the actuator triggers an alarm, shuts down the pump, or performs another programmed function while the pump is running at maximum speed without generating the required pressure - a situation that could result from a pipe break or leak.

This property of the actuator allows the detection of a water leak or a ruptured line. When the end of the characteristic is reached, the actuator triggers an alarm, shuts down the pump, or performs another programmed function while the pump is running at maximum speed without generating the required pressure - a situation that could result from a pipe break or leak.

Stop with check valve control prevents water hammer when the pump stops and the check valve closes. Stop with check valve control smoothly decelerates the pump at a speed close to the closing of the valve.

Stop with check valve control prevents water hammer when the pump stops and the check valve closes. Stop with check valve control smoothly decelerates the pump at a speed close to the closing of the valve.

The VLT® AQUA Drive continually evaluates the pump operating conditions based on internal frequency and power measurements. If the power consumption is too low - which occurs when there is little or no flow - the VLT® AQUA Drive will stop.

The VLT® AQUA Drive continually evaluates the pump operating conditions based on internal frequency and power measurements. If the power consumption is too low - which occurs when there is little or no flow - the VLT® AQUA Drive will stop.

The flow compensation feature of the VLT® AQUA Drive takes advantage of the fact that the flow resistance decreases with decreasing flow. The pressure setpoint is lowered accordingly, thereby achieving additional energy savings.

The flow compensation feature of the VLT® AQUA Drive takes advantage of the fact that the flow resistance decreases with decreasing flow. The pressure setpoint is lowered accordingly, thereby achieving additional energy savings.

Initial acceleration allows the pumps to accelerate quickly to minimum speed, where a transition to normal acceleration occurs. This prevents damage to the pump axial bearings. Final acceleration is used to decelerate the pump from minimum speed to stop.

Initial acceleration allows the pumps to accelerate quickly to minimum speed, where a transition to normal acceleration occurs. This prevents damage to the pump axial bearings. Final acceleration is used to decelerate the pump from minimum speed to stop.

Pump alternation function of Danfoss frequency converters

This built-in logic function allows the alternation of two pumps in a run-standby mode. The movement of the standby pump prevents shaft seizure. An internal timer ensures that both units run evenly.

High efficiency of Danfoss VLT AQUA Drive FC 202 frequency converters - 98%

VLT® Drive Power Modules keep the entire system running without overheating due to low power losses.In modern pumping units, the most widespread is a frequency-controlled electric drive. The basis of this type of drive is a semiconductor frequency converter. They were first used in pumping units at the end of the 60s of the last century.

Danfoss was one of the first to use semiconductor frequency converters in the drive of centrifugal plants. She was the first in the world (since 1968) to produce serial frequency converters used in pumping installations.

Using its many years of experience in the use of frequency converters in this branch of technology, the company has created a series of frequency converters VLT AQUA Driveintended for use in pumping installations of water supply and sewerage systems. VLT AQUA Drive converters are manufactured for drives from 0.37 kW to 1400 kW.

The power factor of the converter is also quite high (cosphi ≥ 0.9), therefore, the use of a variable drive based on the VLT AQUA Drive converter does not require additional devices that increase the cosphi (batteries of static compensators, etc.).

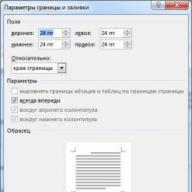

In fig. 1 shows schematic diagram of the VLT AQUA Drive converter and a typical diagram of external connections (power supply, pump motor, sensors, etc.). The appearance of VLT AQUA Drive converters is shown in Fig. 2.

Figure: 1. Wiring diagram for VLT AQUA Drive converter

Figure: 2. Frequency converters "Danfoss" VLT AQUA Drive series

The VLT AQUA Drive is intended for use in pumping installations for water supply, wastewater disposal and irrigation systems. In this regard, it has a number of special functions that provide the properties necessary for working in these conditions, which are listed below.

1. The control system of the converter provides for automatic adjustment of proportional-integral controllers, due to which the gains of the PI controllers are corrected, depending on the reaction of the control object (reservoir-pump-water conduit) to changes in the system operating mode introduced.

Thanks to this property, the PI controller is individually adjusted for each specific object and does not require precise adjustment of the proportional (P) and integral components of the controller when putting the converter into operation.

2. The control system of the VLT AQUA Drive transducer ensures gradual filling of the empty conduit, preventing the risk of water hammer and, consequently, damage to pipes and hydromechanical equipment. This property is especially valuable for irrigation pumping installations, which are quite often included in the work on empty water conduits. The filling of the water conduit is carried out on a signal in several stages.

3. The control system of the VLT AQUA Drive converter has the property of signaling a pressure drop in the pipeline below the set value when the pump reaches the rated speed (point A). This signal indicates the need to turn on an additional pump if a group of pumps is working on the water line.

If a single pump is envisaged to operate on an insulated water conduit, the signal indicates a water rupture or a large water leak from the system. In this case, the pumping unit is turned off, and measures are taken to eliminate the malfunction of the water conduit.

4. The control system of the converter has the ability to regulate the speed of the pump when it stops. Due to this property, the rotational speed is gradually reduced in steps to the rotational speed corresponding to the valve closing moment, which prevents water hammer in the system and mechanical influences on the valve itself.

5. The VLT AQUA Drive inverter control system has the ability to detect dry running. The system continuously evaluates the operating conditions of the pump unit based on the results of measuring the drive parameters (speed and drive power). With a low power consumption, which occurs with too little or no flow, the pump unit stops.

6. The VLT AQUA Drive adjustable frequency drive can operate in sleep mode. This mode is understood as the operation of the pump with a very low flow, which corresponds to a low power consumption. This usually occurs when the pump is running at low speed.

The control system, comparing the pump speed and the power consumed by it, puts the system into "sleep mode". At low flow, the pump raises the pressure to the required value and stops. Further, the control system controls the pressure in the water supply system or the level of effluents in the receiving tank of the sewage station.

When the pressure in the water supply system drops or the level of wastewater in the receiving tank of the pump station rises, the pump is put into operation. Due to the property of the control system to provide a "sleep mode", the wear of the pump unit is reduced, preventing its operation with a small water intake or a small flow of wastewater into the receiving tank of the pump station. The presence of this function of the converter allows to save, on average, 5% of the energy consumed for the water supply.

7. The control system of the VLT AQUA Drive converter has a function due to which the head losses in the water line from the pumping station to the dictating point of the water supply network are taken into account. Thanks to this function, the required head is set at the outlet of the pumping station in accordance with the changing water supply. This takes into account that the pressure loss in the pipes is proportional to the square of the flow rate.

This property makes it possible to provide the required head at the end of the water conduit without a pressure sensor. However, it can be effectively used only in the absence of intermediate water withdrawals at the pipeline.

8. Along with the mentioned properties of the VLT AQUA Drive converter of the control system, the following should be noted:

ensuring smooth start-up with a given starting and stopping rate of the pump, which prevents damage to the pump bearings, reduces the likelihood of water hammer in pipelines, and reduces starting currents in the supply network;

ensuring the alternation of pumping units as working and standby. This ensures uniform wear of the motor resource of the pumping units;

a converter payback indication showing how much time remains until the VLT AQUA Drive has been fully recouped.

1. AEO function (automatic energy optimization function). Thanks to this function, the drive consumes as much energy as is necessary to supply fluid at a given time.

Using this function saves an additional 5 - 10% energy. In addition, this function reduces the consumption of the drive and therefore the load current of the motor. This function is especially effective for mechanisms with a fan moment of resistance (the moment of resistance is proportional to the square of the speed), including for centrifugal pumps. This function also reduces the acoustic noise of the unit.

2. Automatic motor adaptation function built into the inverter. Adjustment of the frequency converter depends significantly on the internal parameters of the electric motor (resistance, inductance, etc.).

The automatic adaptation function allows you to accurately determine the parameters of the motor connected to the inverter and adjust it. This function is important in cases where pump motors are replaced, when the motor parameters are changed after repair, as well as in cases where different types of electric motors are alternately connected to the same converter.

The presence of this function reduces energy consumption by 3 - 5%, and when using repaired electric motors, the savings reach 10%. The use of frequency converters of especially high power is associated with the generation of higher-order harmonics.

The presence of higher harmonics in current leads to overheating of cable conductors, increases losses in transformers, worsening operating conditions. In addition, the insulation of the elements of power supply networks is aging prematurely, the elements of protective devices (automatic devices, fuses) are unreasonably triggered, interference occurs in telecommunication networks located near power cables.

Nowadays, many models of frequency converters are equipped with built-in filters for electromagnetic compatibility (EMC). In particular, to prevent higher current harmonics from entering the external power grid, VLT AQUA Drive frequency converters are equipped with chokes in the intermediate current link to reduce harmonic distortion.